Home - Marine coating systems - Longterm offshore protection

Longterm offshore protection

Offshore units such as FPSOs, FSOs, FLRSUs, floating offshore wind turbines and the like need to stay out of drydock for 15, 25 even 40 years. The challenge has been to protect the underwater hull from corrosion for that time. Also to provide a cleanable surface so that the biofouling that accumulates can be safely removed to reduce weight and for class inspection.

Ecolock, designed specifically to protect offshore vessels for decades without the need for drydocking, is the answer to that challenge.

Long term protection of offshore assets

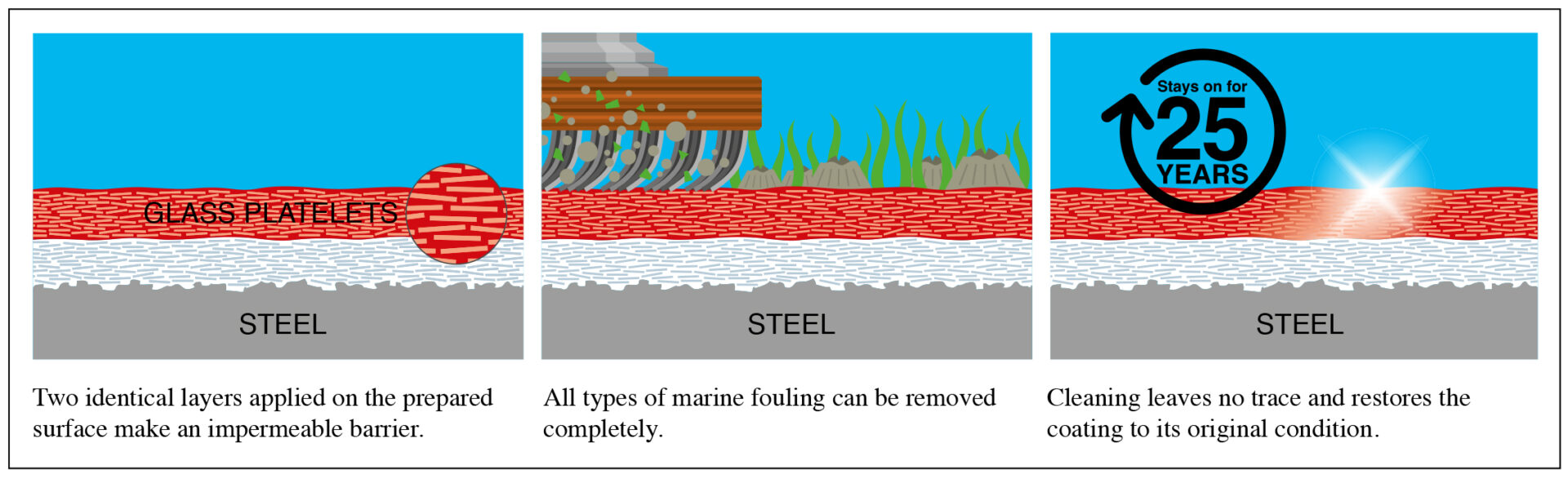

It has long been known that glass reinforced hard coatings last longer, are tougher and more resilient, need less repair and replacement and can be cleaned better in the water than any other type of hull coating.

Soft coatings such as biocidal antifouling and foul-release coatings do not hold up well. They need to be repaired or replaced often which is not good news for shipowners and operators and particularly offshore operators who need to keep their ships out of drydock. Their antifouling or foul-release properties require that the ship move through the water at relatively high speed. On stationary vessels the fouling simply builds up. With Ecolock the fouling, no matter how thick, can be removed whenever needed. There is no damage to coating or environment.

The Ecolock difference

Key features

Hard, impermeable and even the toughest barnacles will not penetrate it.

Non-toxic and harmless to the environment when cleaned underwater.

Can be cleaned as often as needed to meet the UWILD and weight requirements of FPSOs, drill ships and other offshore units without risk of damage.

No undercreep, even in case of minor mechanical damage.

Certified and approved

Offshore

Ecolock is a pre-qualified coating system in accordance with NORSOK standard M-501, Rev. 5, June 2004.

Corrosion

Ecolock’s sister product, Ecospeed, has been given the highest level of effective protection against degradation and corrosion possible under the DNV classification system. Ecolock and Ecospeed have the same anti-corrosive properties.

Abrasion

Ecospeed has been classified by Lloyds as PC6 and PC7 abrasion resistant ice coating. Ecolock has the same abrasion resistance which will protect offshore vessels at waterline and splash zone from abrasion from fenders and other sources.

Contact us for more information or a quote for an upcoming project

Do you have a newbuild or docking coming up that you feel Ecolock would be the perfect fit for? Contact us now and we will answer your questions and provide a quote for the project.

Download the Ecolock Brochure

Further details about Ecolock are available in the Ecolock digital brochure which you can download here.

References, technical materials and further information for download

There is a wealth of information on Ecolock and our other products available in the form of books, white papers, case studies, magazine articles, technical guides, brochures and other literature.