Home - Case studies

Case studies

On this page you can find a selection of the most important operations carried out around the world by our teams over the years.

Palco Marine Services : Agents in Singapore for Subsea Industries and Hydrex

For several years, Palco Marine Services, a long-established and well-known provider of products and services to the thriving Singapore maritime sector, has been actively representing

N. Bogdanos Marine Bureau: Agents in Greece for Subsea Industries and Hydrex

For 11 years now, Subsea Industries and Hydrex have enjoyed a productive and agreeable relationship with N. Bogdanos Marine Bureau as sole representatives for both

Trade-shows and conferences

Subsea Industries and Hydrex attend many of the major international shipping, offshore and related trade-shows, as well as some more specialized exhibitions and conferences. It’s

Ecospeed solves corrosion of scrubber pipes and outlets

Recently our Ecospeed coating system was applied on the scrubber pipes, recycle tanks, outlets and diffusers of a several container ships. This demonstrates that Ecospeed

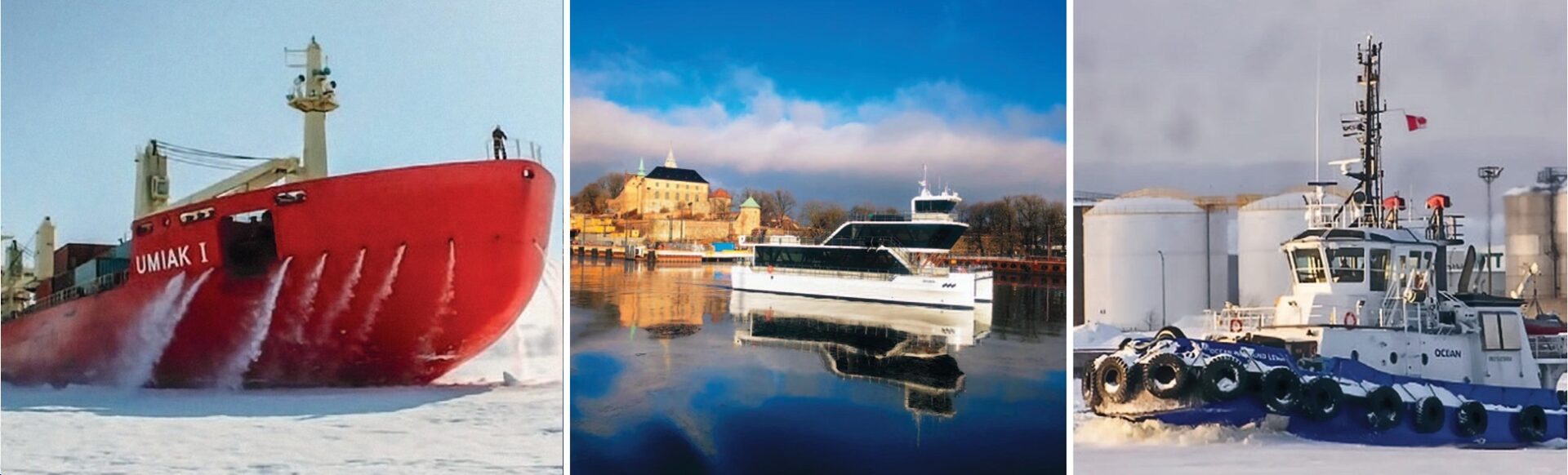

Jastram Technologies Ltd. representing Subsea Industries across Canada

Jastram Technologies Ltd. have been actively representing Subsea Industries in Canada since 2014 for the benefit of their and our many Canadian customers. Canada covers

Yearly review 2023

The past year has been an especially successful one. A large number of new applications were completed for our different coating systems and we achieved

Promising results of Ecoshield test in hopper of Dutra’s TSHD Stuyvesant

Testing of Ecoshield on the Dutra Trailing Suction Hopper Dredger Stuyvesant shows that the coating promises to be a viable solution for protecting the hopper

Ecoshield ideally suited for thruster tunnel protection

Besides offering rudder protection, Ecoshield is also suitable for all underwater ship gear which needs special protection from corrosion. The extra strength coating protects these

Ecoshield protecting increasing numbers of rudders and running gear

Many of the world’s leading shipping companies rely on Ecoshield to protect the rudders, thruster tunnels and other parts of the underwater ship prone to

Our new monthly magazine is now available.

In it you can find information on recent Subsea Industries projects and developments.