The past year has been an especially successful one. A large number of new applications were completed for our different coating systems and we achieved great success with ships coming into drydock after sailing with our coatings for many years. The result is happy quotes from satisfied customers.

In this article we will be looking back at some of the major projects and success stories of 2023.

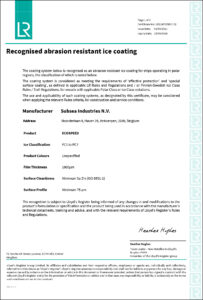

Abrasion-resistant coating certificate for all ice classes

The Lloyd’s Register certificate that recognizes Ecospeed as an abrasion-resistant ice coating has been renewed and upgraded this year. Based on extended observation of the coating in use, Lloyd’s changed the classification from Polar Code 6 & 7 to PC1 to PC7. This once again confirms the durability and strength of the coating and shows the lasting trust in Ecospeed given by the classification societies.

The number one consideration in a hull coating for ice-going vessels and icebreakers is the ability of the coating to protect the hull in the harshest marine environment there is. Only a few types of coatings are capable of providing this protection. Typically they are certified for their ice-abrasion resistance qualities by the classification societies.

The abrasion resistant coating certificate allows owners of vessels of all ice classes to reduce the thickness of the plating of the ice belt if this area is coated with Ecospeed. The ice belt is the area on the bow just above the waterline that is most prone to mechanical damage from sailing through ice.

This saves money since less steel is required to build the hull and reduces the overall weight of the ship.

Group Ocean

Group Ocean have been applying Ecospeed Ice on all their ice going tugs since January 2012. “What we were looking for was a 25-year corrosion protection system for our ice-going tugs,” says Patrick Chabot, Director of Fleet Planning and Renewal at Group Ocean in Québec, Canada. “We do not want to do any corrosion/erosion steel work,” he adds. “I believe we have now found that 25-year solution.”

The Ocean tugboats are generally built for service in harsh, icy conditions. The coating used on the hull is very important for a number of reasons. Group Ocean experimented with several options before finding the right one.

The Ecospeed Ice applied in 2012 is still in excellent condition. Olivier Garon, Director of Fleet Maintenance sees each tug when it comes into drydock. “I am very impressed with the hull condition,” he notes. “When they’re in drydock, I can see right away which vessels were painted with Ecospeed and which were not. The difference is very noticeable. There are maybe just a few little touch-ups to do, probably resulting from mechanical damage rather than from the ice, most likely anchor chain or something like that. The application has been done per instructions, so it lasts. I’m really impressed.”

Zeeland oyster cutter

Pols-Bom, a certified organic oyster cultivation company operating in Zeeland, in The Netherlands has been using Ecospeed for long-lasting, non-toxic protection of the cargo hold of their cutter, YE 48 Op Hoop van Zegen. The coating has held up extremely well for 15 years without need of repainting, requiring only minor touch-ups every few years.

In 2007, Ecospeed was recommended to Mr. Jacques Pols as the ideal coating for the upper part of the YE 48’s hold. Ecospeed was applied in two coats to a dry film thickness (DFT) of 1000 µm or 40 mils. The boat has been in constant use since then and the original coating has not needed to be replaced. In 2013 and again in 2022, Mr. Pols ordered very small quantities of Ecospeed to touch up areas where there was some mechanical damage, but otherwise the coating is protecting the steel as well as it was when first applied. It is in extraordinarily good condition. “I am a very happy customer,” says Mr. Pols.

The 100% non-toxic nature of Ecospeed is an important additional benefit. The oysters are in contact with the coating on the sides of the hold so that if it had any toxicity, it could negate the 100% organic certification.

Brim Explorer

In 2023 the energy-efficient sightseeing ferry MS Brisen was baptized in Oslo, Norway. The carbon fiber vessel was built at the Brødrene Aa shipyard in Hyen, for ferry operator Brim Explorer. The ship’s hull is protected with our non-toxic, hard coating system Ecospeed which is expected to last the ferry’s lifetime. Sister vessel MS Berg has received the same protection.

“Applying Ecospeed is quite easy if you have some experience applying paint with a spray gun,” says spray paint specialist Torgeir “Toggen” Ulleland who performed the application on MS Brisen.

Going forward Brim Explorer have chosen Ecospeed for their fleet because they are concerned with all environmental aspects of their operation. “With Ecospeed we eliminate all chemical emissions to the sea, preventing harmful chemicals from disturbing the fragile ecosystems in the areas in which we operate,” says Espen Larsen-Hakkebo, CEO and Co-founder of Brim Explorer. “Our business is creating unforgettable experiences: it only makes sense to do this causing as little impact to the environment as possible. Ecospeed is therefore our preferred choice over any antifouling system.”

Scrubbers

Last year our Ecospeed coating system was applied on the scrubber pipes, outlets and diffusers of a large number of ships. This demonstrates that Ecospeed is not only the best option for the underwater hull of a ship but can also be used for a wide range of other purposes. The result is a lasting, non-toxic protection against corrosion, cavitation and mechanical damage.

Because of the tight regulations on emissions in the shipping industry, the installation of an exhaust scrubber system has become increasingly widespread. Due to the highly corrosive nature of the effluents from scrubbers, this unfortunately has also led to an increase of corrosion damage on scrubber pipes and outlets which can result in water ingress into the engine room, ballast tanks and cargo holds.

Ecospeed however is highly chemically resistant. Using the coating to protect the exterior outlets as well as the interiors of scrubbers prevents corrosion damage and the resulting consequences.

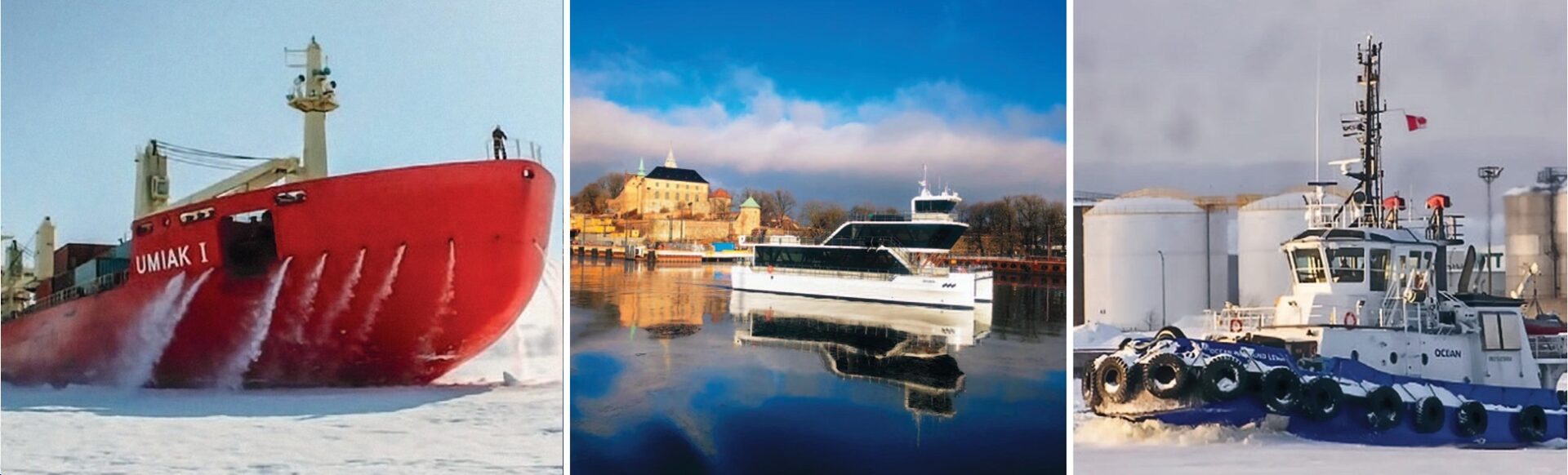

Umiak I

In April 2021, Fednav’s Umiak I, one of the world’s most powerful icebreaking cargo ships, had the entire hull from keel to gunnel coated with Ecospeed Ice, replacing the existing hull coating. Two years later the coating is in great shape.

Craig Verge, the superintendent of the Umiak I says, “I was out and had a look at the hull coating in Long Harbor, [near St. John’s in Newfoundland & Labrador, Canada].” Craig works for Canship Ugland Ltd., the St. John’s N.L. based ship management company that manages a variety of vessels including this 189-meter icebreaking bulk carrier. “The Ecospeed is holding up well – as far as I can see there does not appear to be any damage from ice whatsoever,” he says, “There is also only minimal mechanical damage from chains on fenders and tugs, and marks from tires.” This report is from August 2023, more than two full years of service since the ship’s hull coating was changed to Ecospeed Ice.

As can be expected, the hull coating on the Umiak I is subjected to some of the harshest treatment any hull coating can receive. The original coating was not holding up as well as desired. Thus it was that in the ship’s 2016 drydocking, it was decided to apply two test patches of Ecospeed Ice. For the next five winter seasons, the test patches were closely monitored and found to be holding up remarkably well.

Looking back on that decision, in light of the results shown by the recent inspection after two years of the Umiak I’s sailing with Ecospeed Ice, David Williams, Senior Manager, Technical Services Fleet Management at Fednav said: “Fednav has operational experience with various ice resistant hull coatings over our history as owners and operators of ice class vessels. Service experience with Ecospeed test patches, and later a full application of Ecospeed, on the Umiak I has demonstrated to us that Ecospeed is the leading hull coating product, of those we have tested, for this application.”

Ecoshield for rudders and running gear

In 2023 we carried out well over 100 Ecoshield applications on rudders and running gear. These were done at yards across the world on a wide range of ships.

Many of the world’s leading shipping companies rely on Ecoshield to protect the rudders, thruster tunnels and other parts of the underwater ship prone to cavitation erosion and chemical corrosion. Several of these companies have been using Ecoshield successfully for a decade or more. Others are newer to the product but are wasting no time in putting it to use.

To date there have been at least 700 separate Ecoshield applications to rudders, thruster tunnels, Kort nozzles, energy saving devices such as Becker Twisted Fins®, thrusters, stabilizer fins, sea chests, Hull Vanes®, bulbous bows and other parts of the underwater ship hull and running gear that need special protection from the effects of cavitation.

An extraordinary fact we discovered about Ecoshield is that it need only be applied once. It lasts the life of the vessel without the need for repainting beyond minor touch-ups of mechanical damage. We found this out when ships were coming into drydock ten years after the original Ecoshield application and only needing a couple of liters of paint for retouching mechanical damage.

Experience also showed that Ecoshield properly applied makes the use of sacrificial anodes unnecessary. This has been proven time after time.

Dutra’s TSHD Stuyvesant

Testing of Ecoshield on the Dutra Trailing Suction Hopper Dredger Stuyvesant shows that the coating promises to be a viable solution for protecting the hopper of a dredger.

Dredgers generally experience high wear as a result of their normal activities. In the case of the Stuyvesant, this occurs mainly on the flat bottom and inside the hopper. To try to mitigate some of the wear and reduce the need for steel replacement and repair, in August 2022 Dutra Fleet Manager Iain Searle decided to run tests of Ecoshield on parts of the Stuyvesant that were particularly prone to abrasion damage.

Inspection of the hopper was carried out in mid-June 2023 which is 10 months after application. The dredger had been in normal use during that period.

Iain was very pleased with the results. “To be honest,” he said, “I was expecting it to be gone in a few weeks, so I am surprised it is holding up at all.”

Overall, the coating is all in place and looking surprisingly good, considering the constant barrage of dredged material to which it is subjected. Clearly since the coating is intact, no damage to the steel has occurred and there has been no erosion or corrosion.

Conclusion

These are just a handful of the successes we have had in 2023, but we are very proud to have been able to help so many shipowners protect their valuable ships and boats and save large amounts of money in the process.