Home - Marine coating systems - Ice-going hulls

Ice-going hulls

Ecospeed Ice is the proven, ultimate hull protection for icebreakers and ice-going vessels. It is designed and formulated to last the life of the vessel with no need for replacement, requiring only minor touch-ups during routine drydocking. Backed by an unheard-of 10-year warranty, Ecospeed Ice simply stays on the hull no matter the conditions of sea and ice.

Ice-class coating in a class of its own

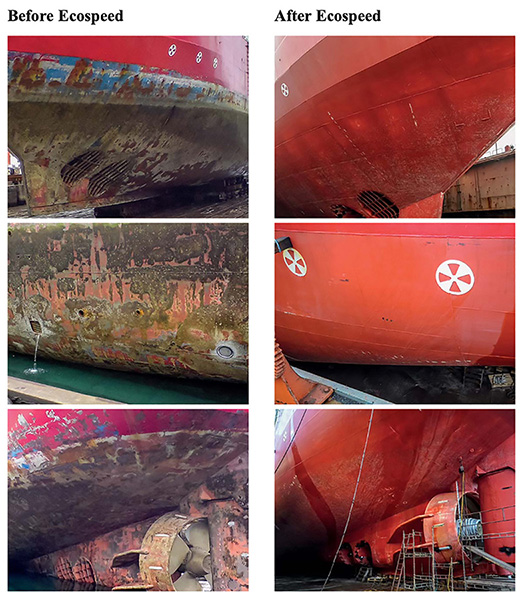

The before/after photos tell the story better than any words can.

Three photos on the left side show the hull of an Antarctic research and supply ship coated with the most popular, traditional ice-class coating after a single season in the ice.

The photos on the right side show the same hull of the same ship after four seasons in the ice after being coated with Ecospeed Ice, no repaint and only minor touch-ups during routine drydocking.

But the story continues. Below are three photos of the same ship, now rechristened and under new ownership, in 2021, a full 12 years after the original application of Ecospeed Ice with no repainting during that time, despite season after season of pounding her way through 1.5 meter ice with additional stress from lava and other highly abrasive material found in Antarctic ice.

Why Ecospeed Ice?

• Class certified ice abrasion-resistant coating.

• Low friction. The hull remains smooth and retains its low friction properties for the life of the ship, saving fuel and reducing emissions.

• Due to superior protection, newbuilds are able to take advantage of reduced scantlings, less steel and a lighter ship, saving construction costs.

• A base consisting of a resin which cures fully without becoming brittle or inflexible and has superior adhesion properties, reinforced with a high content of large aspect ratio glass platelets.

• Extraordinarily tough bonding powers. Ecospeed Ice contains a number of ingredients to improve bonding and strength. Even in the event of mechanical damage, there will be no undercreep.

• Completely non-toxic. Vital for pristine polar regions and other sensitive environments. Will not leave biocides or heavy metals in the ice.

• Preparation includes grit blasting to create a profile of at least 75 µm and a cleanliness of SA 2.5 or better.

• Easily applied without specialized equipment such as hot twin-feed guns, or restrictive environmental conditions such as temperature or humidity. No primer. Just 2, 3 or 4 coats (usually 2) each 500 µm DFT. Rapid overcoat time of about 3 hours. Ready to launch in 24 hours.

• The coating remains intact and smooth for many years in the harshest of icy waters and will not need to be replaced. Only minor spot repairs for mechanical damage are required during routine dry-docking. Any repairs blend in, leaving the hull as smooth as on initial application of the coating.

• Easy to clean in-water or in drydock to remove biofouling whenever this builds up (not frequent with ice-going vessels). Cleaning does no harm to the hull coating – in fact, in-water cleaning improves it.

References, technical materials and further information for download

There is a wealth of information on Ecospeed available in the form of books, white papers, case studies, magazine articles, technical guides, brochures and other literature.

Contact us for more information or a quote for an upcoming project

Do you have a newbuild or docking coming up that you feel Ecospeed Ice would be the perfect fit for? Contact us now and we will answer your questions and provide a quote for the project.