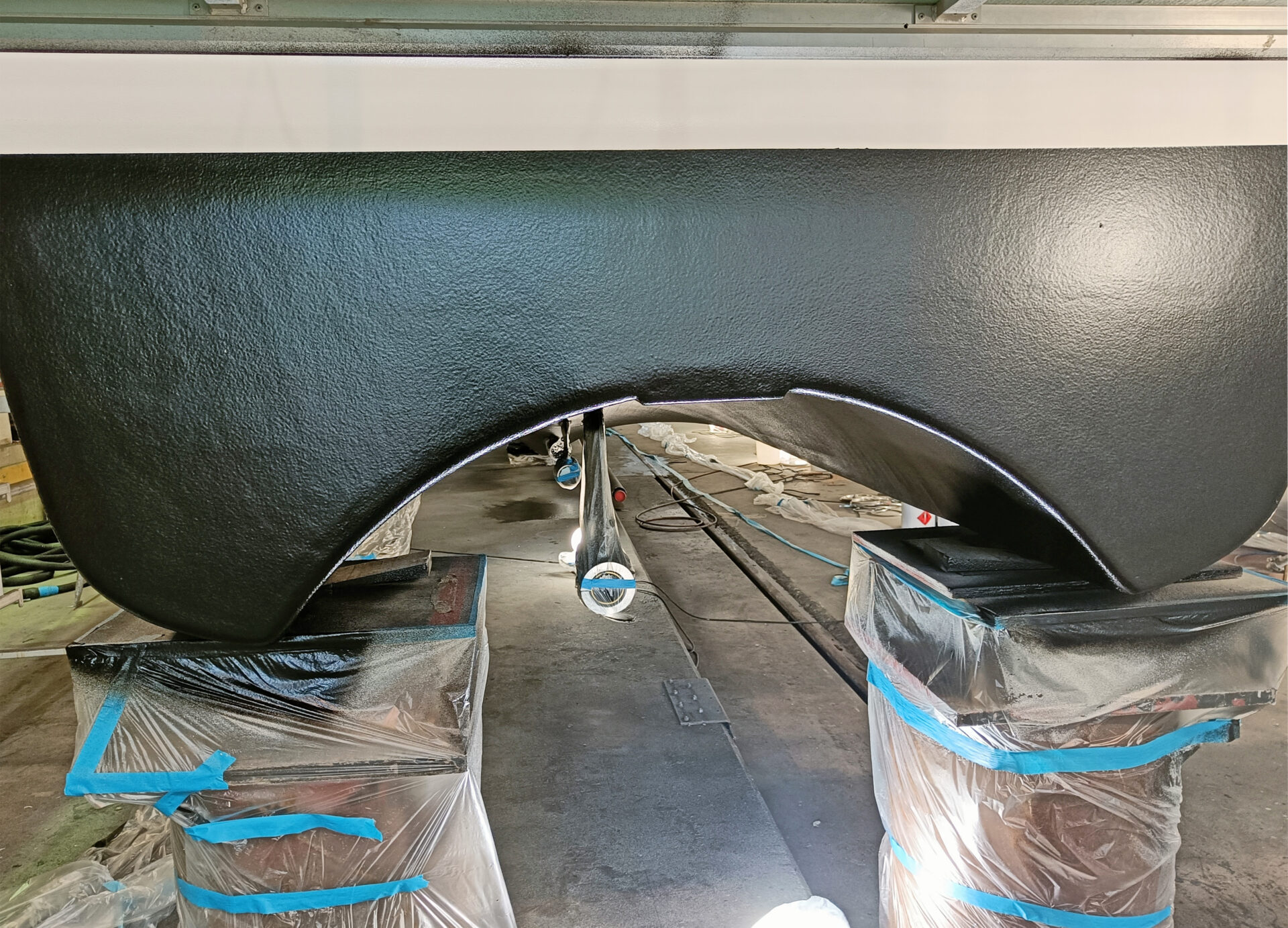

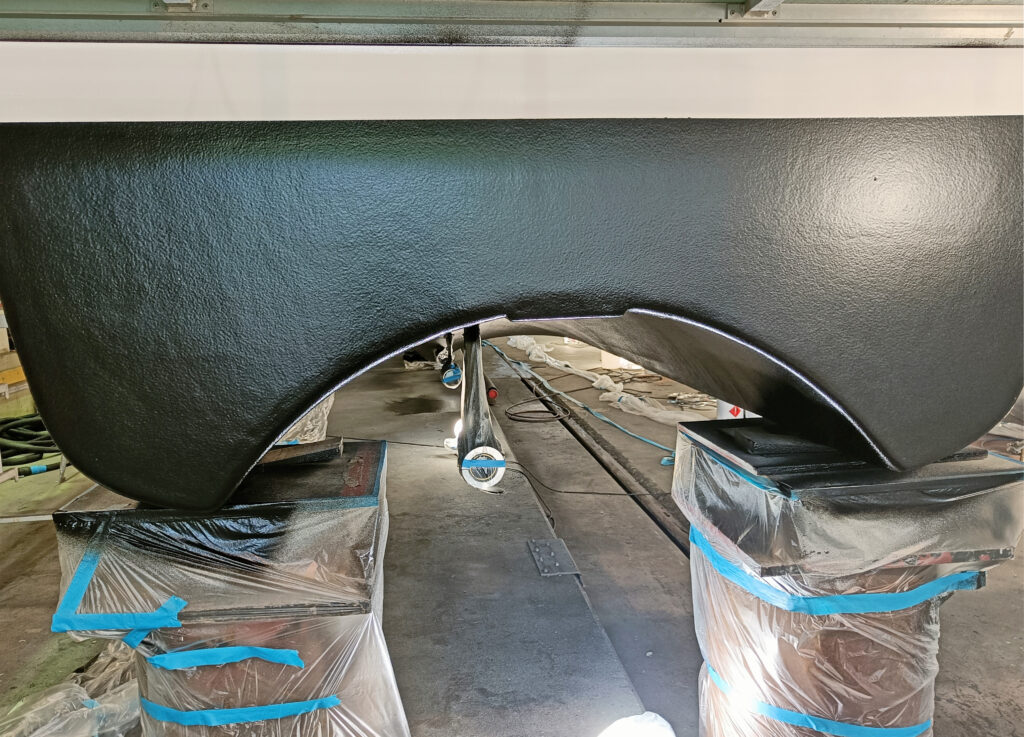

Last month the energy-efficient sightseeing ferry MS Brisen was baptized in Oslo, Norway. The carbon fibre vessel was built at the Brødrene Aa shipyard in Hyen, for ferry operator Brim Explorer. The ship’s hull is protected with our non-toxic, hard coating system Ecospeed which is expected to last the ferry’s lifetime.

Owner Brim Explorer is a tourism and ship-owning company investing in, and operating hybrid-electric and electric ships. The company offers silent, sustainable and innovative experiences at sea in Northern Norway and, since recently, also in Oslo. Their first ship Brim operates in Lofoten and Tromsø, and their second ship Berg operates in Svalbard and Tromsø. The third ship in the fleet, MS Brisen, is completely electric and will operate in Oslo. The design of all the ships prioritizes the experience of the guest, and creating minimal impact on the environment. They are unique in the world.[1]

Brim Explorer strictly follows national and international laws, regulations and guidelines as well as company standards in regard to pollution prevention and animal welfare. When encountering marine mammals and other wildlife they follow the whale watching guidelines of Visit Tromsø. They believe in protecting and preserving the ocean by sharing its life, vulnerability, and majesty.[2]

Stunning design with a breath-taking view

Brødrene Aa is a world leader in the construction of fast ferries made of carbon fiber composites. They have two shipyards. The MS Brisen was built at the Hyen shipyard which employs 170 skilled workers. Hyen is a village near the end of the Hyefjorden on the west coast of Norway, and you would be hard-pressed to find a more idyllic location for the design and construction of environmentally friendly vessels.

The yard is named after the brothers Olav Aa (1920-2006) and Bertel Aa (1919-2009), who founded the company in 1947. Brødrene Aa has built a comprehensive range of boats over the past 60 years. In the 1940s and 1950s the yard made leisure crafts in mahogany. Gradually larger passenger ferries were built in wood. In the mid-1970s the company switched to composite materials building the first ever GRP-Sandwich vessel approved by DNV.

By exploiting composite production expertise, they re-entered the fast-ferry business in the early 2000s with the world’s first commercial passenger vessel made in carbon fibre. This technology-breakthrough has led to a new era of shipbuilding for Brødrene Aa.

The yard in Hyen is modern and well suited for manufacturing of composite products. It has a total of 3000 square meters of indoor facilities, fully moisture-and temperature controlled.[3]

Built in light weight carbon fiber sandwich, featuring an advanced slender hull, the passenger line consists of highly fuel-efficient and environmentally friendly vessels. By utilizing the advantages of carbon fiber reinforced composites, the structural weight is reduced by 40% compared to aluminum.

MS Brisen is a 25.3 m catamaran providing tourists and travellers a zero-emission sailing experience. With room for 149 passengers, the vessel boasts a characteristic and purpose-built design optimized for sightseeing and functions.[4]

“Applying Ecospeed is quite easy if you have some experience applying paint with a spray gun,” says spray paint specialist Torgeir “Toggen” Ulleland who performed the application on MS Brisen.

Nick DeLashmutt, project manager at Brødrene Aa was also very satisfied with how the project was handled. “We appreciate the good cooperation and support from GearConsult and Subsea Industries throughout the various project phases which helped contribute to the successful application of Ecospeed.”

The perfect coating for a revolutionary ship

“In 2018 I got to know the owners of Brim Explorer at a shipping event,” recalls Mr. Ludvig Nyquist, CEO and manager for GearConsult, who represents Subsea Industries in Norway. “They showed an interest in green solutions, but we did not have anything that fit their vessel type at that time. When I met Subsea Industries at Nor Shipping in 2019 and learned about Ecospeed, I thought that it would be a perfect product for Brim Explorer. They were also at Nor Shipping so I introduced the two companies.”

Ludvig continues, “The owners of Brim Explorer liked Ecospeed and wanted to use it on their two first aluminum vessels, Brim and Berg. However, for practical reasons they were not able to go ahead with the order at that time. This is a decision they have regretted since. When it came time to build Brisen they were very clear that they wanted to use Ecospeed on this vessel. They will also use Ecospeed on their next two newbuildings.”

Going forward Brim Explorer have chosen Ecospeed for their fleet because they are concerned with all environmental aspects of their operation. “With Ecospeed we eliminate all chemical emissions to the sea, preventing harmful chemicals from disturbing the fragile ecosystems in the areas in which we operate,” says Espen Larsen-Hakkebo, CEO and Co-founder of Brim Explorer. “Our business is creating unforgettable experiences: it only makes sense to do this causing as little impact to the environment as possible. Ecospeed is therefore our preferred choice over any antifouling system.”

[1] Source: https://brimexplorer.com/about-us

[2] Source: https://brimexplorer.com/sustainability

[3] Source: https://www.braa.no/about

[4] Source: https://www.braa.no/passenger

Last month the energy-efficient sightseeing ferry MS Brisen was baptized in Oslo, Norway. The carbon fibre vessel was built at the Brødrene Aa shipyard in Hyen, for ferry operator Brim Explorer. The ship’s hull is protected with our non-toxic, hard coating system Ecospeed which is expected to last the ferry’s lifetime.

Owner Brim Explorer is a tourism and ship-owning company investing in, and operating hybrid-electric and electric ships. The company offers silent, sustainable and innovative experiences at sea in Northern Norway and, since recently, also in Oslo. Their first ship Brim operates in Lofoten and Tromsø, and their second ship Berg operates in Svalbard and Tromsø. The third ship in the fleet, MS Brisen, is completely electric and will operate in Oslo. The design of all the ships prioritizes the experience of the guest, and creating minimal impact on the environment. They are unique in the world.[1]

Brim Explorer strictly follows national and international laws, regulations and guidelines as well as company standards in regard to pollution prevention and animal welfare. When encountering marine mammals and other wildlife they follow the whale watching guidelines of Visit Tromsø. They believe in protecting and preserving the ocean by sharing its life, vulnerability, and majesty.[2]

Stunning design with a breath-taking view

Brødrene Aa is a world leader in the construction of fast ferries made of carbon fiber composites. They have two shipyards. The MS Brisen was built at the Hyen shipyard which employs 170 skilled workers. Hyen is a village near the end of the Hyefjorden on the west coast of Norway, and you would be hard-pressed to find a more idyllic location for the design and construction of environmentally friendly vessels.

The yard is named after the brothers Olav Aa (1920-2006) and Bertel Aa (1919-2009), who founded the company in 1947. Brødrene Aa has built a comprehensive range of boats over the past 60 years. In the 1940s and 1950s the yard made leisure crafts in mahogany. Gradually larger passenger ferries were built in wood. In the mid-1970s the company switched to composite materials building the first ever GRP-Sandwich vessel approved by DNV.

By exploiting composite production expertise, they re-entered the fast-ferry business in the early 2000s with the world’s first commercial passenger vessel made in carbon fibre. This technology-breakthrough has led to a new era of shipbuilding for Brødrene Aa.

The yard in Hyen is modern and well suited for manufacturing of composite products. It has a total of 3000 square meters of indoor facilities, fully moisture-and temperature controlled.[3]

Built in light weight carbon fiber sandwich, featuring an advanced slender hull, the passenger line consists of highly fuel-efficient and environmentally friendly vessels. By utilizing the advantages of carbon fiber reinforced composites, the structural weight is reduced by 40% compared to aluminum.

MS Brisen is a 25.3 m catamaran providing tourists and travellers a zero-emission sailing experience. With room for 149 passengers, the vessel boasts a characteristic and purpose-built design optimized for sightseeing and functions.[4]

“Applying Ecospeed is quite easy if you have some experience applying paint with a spray gun,” says spray paint specialist Torgeir “Toggen” Ulleland who performed the application on MS Brisen.

Nick DeLashmutt, project manager at Brødrene Aa was also very satisfied with how the project was handled. “We appreciate the good cooperation and support from GearConsult and Subsea Industries throughout the various project phases which helped contribute to the successful application of Ecospeed.”

The perfect coating for a revolutionary ship

“In 2018 I got to know the owners of Brim Explorer at a shipping event,” recalls Mr. Ludvig Nyquist, CEO and manager for GearConsult, who represents Subsea Industries in Norway. “They showed an interest in green solutions, but we did not have anything that fit their vessel type at that time. When I met Subsea Industries at Nor Shipping in 2019 and learned about Ecospeed, I thought that it would be a perfect product for Brim Explorer. They were also at Nor Shipping so I introduced the two companies.”

Ludvig continues, “The owners of Brim Explorer liked Ecospeed and wanted to use it on their two first aluminum vessels, Brim and Berg. However, for practical reasons they were not able to go ahead with the order at that time. This is a decision they have regretted since. When it came time to build Brisen they were very clear that they wanted to use Ecospeed on this vessel. They will also use Ecospeed on their next two newbuildings.”

Going forward Brim Explorer have chosen Ecospeed for their fleet because they are concerned with all environmental aspects of their operation. “With Ecospeed we eliminate all chemical emissions to the sea, preventing harmful chemicals from disturbing the fragile ecosystems in the areas in which we operate,” says Espen Larsen-Hakkebo, CEO and Co-founder of Brim Explorer. “Our business is creating unforgettable experiences: it only makes sense to do this causing as little impact to the environment as possible. Ecospeed is therefore our preferred choice over any antifouling system.”

[1] Source: https://brimexplorer.com/about-us

[2] Source: https://brimexplorer.com/sustainability

[3] Source: https://www.braa.no/about

[4] Source: https://www.braa.no/passenger