Ecolock is a comprehensive solution to corrosion in the hulls, immersed parts, and splash zones of offshore assets, including oil and gas exploration, production and storage units, as well as offshore renewable energy structures. It is of inestimable value to the offshore energy industry as a whole.

The corrosion problem

A NACE International study estimated the annual global cost of corrosion in 2013 at $2.5 trillion, which is about 3.4% of the world’s GDP[1].

Corrosion costs the maritime industry between $50 and $80 billion annually not including indirect costs.[2]

“Some facts may explain why corrosion is so costly:

- 5 metric tons of steel disintegrate every second worldwide.

- 40% of all produced steel is used to replace corroded steel.

- 60% of the world offshore fleet is past its theoretical design age of 20 years, including 6,000 stationary platforms that cannot be moved.

- Offshore maintenance is 15 – 20 times more costly than performing work at a yard.

- Corrosion can account for 60% of offshore maintenance costs.

- At least a portion of the cost can be attributed to coating failure.

Experience has shown that specifying appropriate coating systems and giving sufficient priority to coating related work during the project (CAPEX) phase, will result in significant savings as well as Health, Safety and Environment (HSE) benefits during the operational phase (OPEX).

And yet, corrosion protection by the use of coatings is one of the activities frequently given low priority during the CAPEX phase, very often resulting in high maintenance cost during operation.

A study performed by the Norwegian oil and gas association concluded that all FPSOs (Floating Production Storage and Offloading) in operation have suffered from inadequate paint work and that painting of FPSOs is a critical area to ensure low maintenance.”[3]

The NACE International report concluded, “By using available corrosion control practices, it is estimated that savings of between 15 and 35% of the cost of corrosion could be realized; i.e., between US$375 and $875 billion annually on a global basis, an astronomical savings.”

Together, all these facts and figures point in one, clear direction: at newbuild or when converting an existing tanker to an FPSO or seeking an extended life for an offshore asset, it is vital to:

- Choose a suitable coating for the expected life of the hull

- Insist on adequate surface preparation

- Apply the coating standardly.

Current measures in general use

The traditional measures currently in use for protecting offshore assets from corrosion can be summarized:

- Design of hulls to reduce corrosion

- Choice of materials

- General protective coatings such as epoxies

- Cathodic protection systems (ICCP and/or SACP)

- Cathodically protective pigments such as zinc – corrosion inhibitors

- Increased plate thickness.

These measures try to protect the steel as well as possible and then attempt to contain or minimize the corrosion which inevitably occurs anyway. They are often used in combination in an attempt to mitigate corrosion.

Where these solutions fail:

- The coating starts to break down, for one or more of a number of reasons, exposing the underlying steel to corrosion

- The cathodic protection system is inadequate to prevent the resulting corrosion

- The corrosion inhibitors do not prevent the corrosion.

- The corrosion sources combine to accelerate the corrosion process so that in some cases the corrosion proceeds amazingly rapidly.

The weakest link

This fatal downward spiral begins with a failure of the protective coating. This is the weakest link and the Achilles heel in corrosion protection. It is also the entrance point for dealing with the problem.

The key to cracking corrosion in offshore assets

The key to solving the corrosion problem lies in the coating. The steel can and must be fully coated and insulated against seawater and all corrosive elements such as biofouling, with a tough, durable, impermeable coating so that no corrosive elements can reach the substrate.

The coating must remain intact for the 20-40 year period usually required by the offshore oil, gas and renewables industries.

This is our approach to dealing with the corrosion problem in offshore vessels and structures. The right coating, standardly applied, is capable of cracking the problem of corrosion in offshore assets.

BUT, this requires careful choice of coating system by the owner and project managers, and insistence that the yard be willing to deliver the full surface preparation required, whether at newbuild or during conversion. Also the owner must insist on the use of the specified, correct coating system and not just “do what we’ve always done.” It will be too late to remedy if these steps are not done and the coating fails after a few years.

If these measures are scrupulously followed, the owner can expect a trouble- and maintenance-free life of the hull or underwater parts of the offshore asset.

Which brings us to ECOLOCK

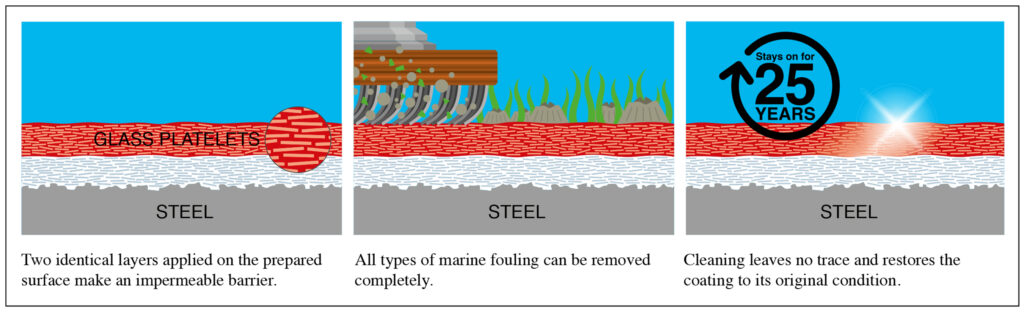

Ecolock is a completely non-toxic, hard, durable coating designed specifically to protect offshore assets for decades. It consists of a high concentration of large aspect ratio platelets of special glass in a vinyl ester resin base with added bonding agents to improve adhesion.

Glass is a perfect insulator. Vinyl ester is the acknowledged best, longest-lasting resin available for these purposes, superior to epoxies and polyesters. While epoxies tend to be somewhat porous and to become brittle over time, vinyl ester suffers from neither of these faults.

Ecolock has been formulated to provide complete, long-lasting insulation of the steel from all corrosive elements.

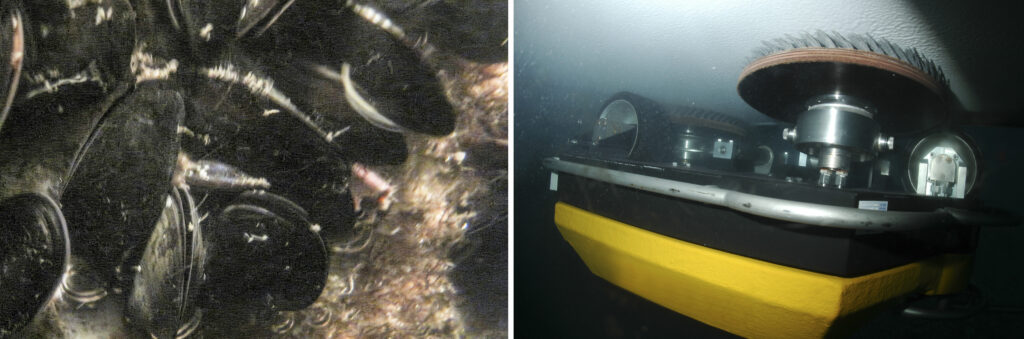

In time, biofouling will accumulate on any submerged structure or vessel regardless of coating. With Ecolock, marine growth of any thickness can be removed at any time to reduce weight,

Application

Ecolock is easy to apply and to repair if needed. The surface to be coated must be blasted to SA 2 1/2 with a minimum 75µm (3 mil) roughness profile. It is applied by single feed airless spray. There is a minimum overcoat time of three hours and no maximum, which is particularly convenient for newbuild applications. The vessel can be launched 24 hours after application.

Note that Ecolock is applied directly to prepared steel. There is no primer, no tie coat and no topcoat. Just one, homogenous layer of Ecolock applied in two coats each 500 µm (20 mil) DFT. A third coat can be added for specific situations.

Many users have found that, when Ecolock is correctly applied, there is no need for anodes or cathodic protection of any kind. Since the steel is fully insulated, galvanic corrosion is not an issue.

The life expectancy of Ecolock correctly applied exceeds 25 years.

In part 2 we will feature some case studies of Ecolock to illustrate the above features and advantages of Ecolock in the real world of offshore assets.

[1] Source: NACE IMPACT report http://impact.nace.org/executive-summary.aspx

[2] Source: GlobalSpec Engineering 360 Newsdesk

[3] Source: Corrosion protection and the cost of failure, by Lasse Isaksen, ABRACO’s INTERCORR 2014 congress