In May Ecoshield was applied to the Hull Vane intended for an ocean-going patrol vessel or OPV. Application was done by Straalbedrijf Schep en zonen BV at their location in Nieuwerkerk aan den Ijssel, the Netherlands.

Hull Vane is a Dutch invention designed by Hull Vane BV. It consists of a submerged transom wing at the stern of the ship or boat which renders ships more efficient and quieter, while improving their seakeeping. It essentially converts the stern wave’s energy into forward thrust.

This Hull Vane will be installed in 2023 on the aft ship of a 108-meter, Holland Class patrol ship.

“It is by far the largest Hull Vane ever built and the first one to be installed on a naval ship,” says Niels Moerke, managing director at Hull Vane BV. “Hull Vane works great on this kind of ship and provides a number of benefits. Maximum performance and employability were the goal, but we have had to comply with a number of additional requirements. Fortunately, we have proven to be able to fulfil these. We are also aware that foreign navies are monitoring this project with keen interest and the intention to follow the Dutch Navy.”

Besides energy saving, which automatically leads to a reduction of CO2 emissions, the Hull Vane also offers many tactical advantages for the ship. Due to the suppressed stern wave, the vessel leaves much less obvious wake, making her less visible to satellites, drones and even certain types of torpedoes. The ship will have a higher top speed, and will be able to cross a long distance faster, e.g., when being deployed for emergencies. But above anything else, the goal is to reduce the dependency on diesel fuel. That is valuable in peace time, but even more so during war.[1]

[1] Source: https://www.hullvane.com

An innovative coating for an innovative product

Nowadays, computational fluid dynamics (CFD) is used to customize and optimize the design of the Hull Vane for many vessels. It is therefore important that the device be given the best possible protection.

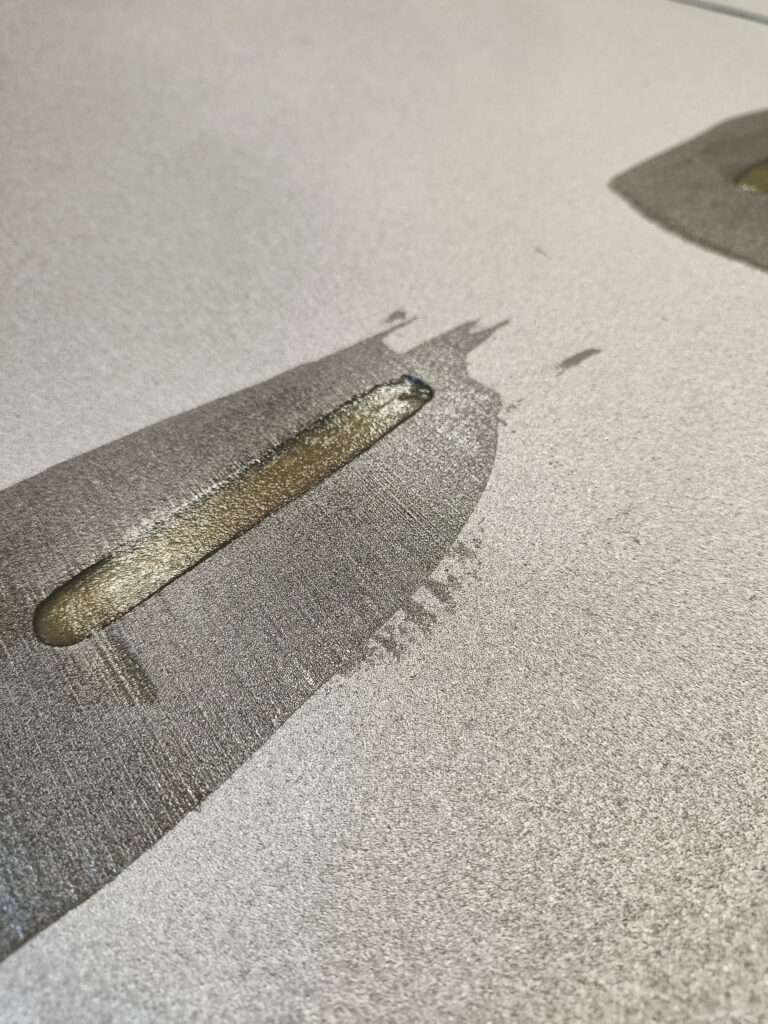

There is no better coating suited for this task than Ecoshield. A thick vinyl ester base with a very high concentration of glass platelets forms the impenetrable barrier needed to resist corrosion. Applied at newbuild, it will provide lifetime protection.

Ecoshield is primarily used to protect rudders and other running gear, but it can be used to safeguard any area that needs special protection from corrosion and cavitation damage. The extra strength coating protects these areas for the service life of the ship. There is no need for recoating or major repair.

Evidence of the success of the coating is the number of companies that began by coating one rudder experimentally and have ordered Ecoshield for the running gear on other ships after seeing the results in service. Most have plans to convert their entire fleet. Shipowners who have previously applied Ecoshield to rudders on ships in service are specifying the coating for the rudders and other underwater gear on their newbuilds.

Conclusion

At Subsea Industries we are proud to be part of such an exciting project. We are looking forward to working together again with this innovative company and provide our coating systems for many more Hull Vanes.

In May Ecoshield was applied to the Hull Vane intended for an ocean-going patrol vessel or OPV. Application was done by Straalbedrijf Schep en zonen BV at their location in Nieuwerkerk aan den Ijssel, the Netherlands.

Hull Vane is a Dutch invention designed by Hull Vane BV. It consists of a submerged transom wing at the stern of the ship or boat which renders ships more efficient and quieter, while improving their seakeeping. It essentially converts the stern wave’s energy into forward thrust.

This Hull Vane will be installed in 2023 on the aft ship of a 108-meter, Holland Class patrol ship.

“It is by far the largest Hull Vane ever built and the first one to be installed on a naval ship,” says Niels Moerke, managing director at Hull Vane BV. “Hull Vane works great on this kind of ship and provides a number of benefits. Maximum performance and employability were the goal, but we have had to comply with a number of additional requirements. Fortunately, we have proven to be able to fulfil these. We are also aware that foreign navies are monitoring this project with keen interest and the intention to follow the Dutch Navy.”

Besides energy saving, which automatically leads to a reduction of CO2 emissions, the Hull Vane also offers many tactical advantages for the ship. Due to the suppressed stern wave, the vessel leaves much less obvious wake, making her less visible to satellites, drones and even certain types of torpedoes. The ship will have a higher top speed, and will be able to cross a long distance faster, e.g., when being deployed for emergencies. But above anything else, the goal is to reduce the dependency on diesel fuel. That is valuable in peace time, but even more so during war.[1]

An innovative coating for an innovative product

Nowadays, computational fluid dynamics (CFD) is used to customize and optimize the design of the Hull Vane for many vessels. It is therefore important that the device be given the best possible protection.

There is no better coating suited for this task than Ecoshield. A thick vinyl ester base with a very high concentration of glass platelets forms the impenetrable barrier needed to resist corrosion. Applied at newbuild, it will provide lifetime protection.

Ecoshield is primarily used to protect rudders and other running gear, but it can be used to safeguard any area that needs special protection from corrosion and cavitation damage. The extra strength coating protects these areas for the service life of the ship. There is no need for recoating or major repair.

Evidence of the success of the coating is the number of companies that began by coating one rudder experimentally and have ordered Ecoshield for the running gear on other ships after seeing the results in service. Most have plans to convert their entire fleet. Shipowners who have previously applied Ecoshield to rudders on ships in service are specifying the coating for the rudders and other underwater gear on their newbuilds.

Conclusion

At Subsea Industries we are proud to be part of such an exciting project. We are looking forward to working together again with this innovative company and provide our coating systems for many more Hull Vanes.

[1] Source: https://www.hullvane.com