Some time ago we published an article about the independent paint inspectors who play such an important role in making sure that our coatings are correctly applied and provide maximum protection for the longest time. (read the article here). In this article we talk to two more: Marcin Zabiello and Mehmet Acer. They provide different viewpoints and further insights into why Ecoshield and Ecospeed have had such excellent success.

Marcin Zabiello

Marcin Zabiello, based in Gdynia, Poland, has worked in the corrosion protection industry for over 20 years, and has been an Independent Paint Inspector since 2016. He provides his services internationally at CERICON (Certified Inspector Consultancy) and has carried out many application inspections for Subsea Industries including full hulls, rudders, ice belts, azipods and others.

Marcin has been a NACE Level III paint inspector since 2010. He has worked independently for a number of different companies and has a very wide experience, specializing in marine coatings but also in other fields such as offshore projects, port cranes and bridges.

We interviewed Marcin on the subject of his experiences with Ecospeed, Ecoshield and Ecofix.

SI: What is your experience with Subsea Industries and the Ecospeed family of coatings?

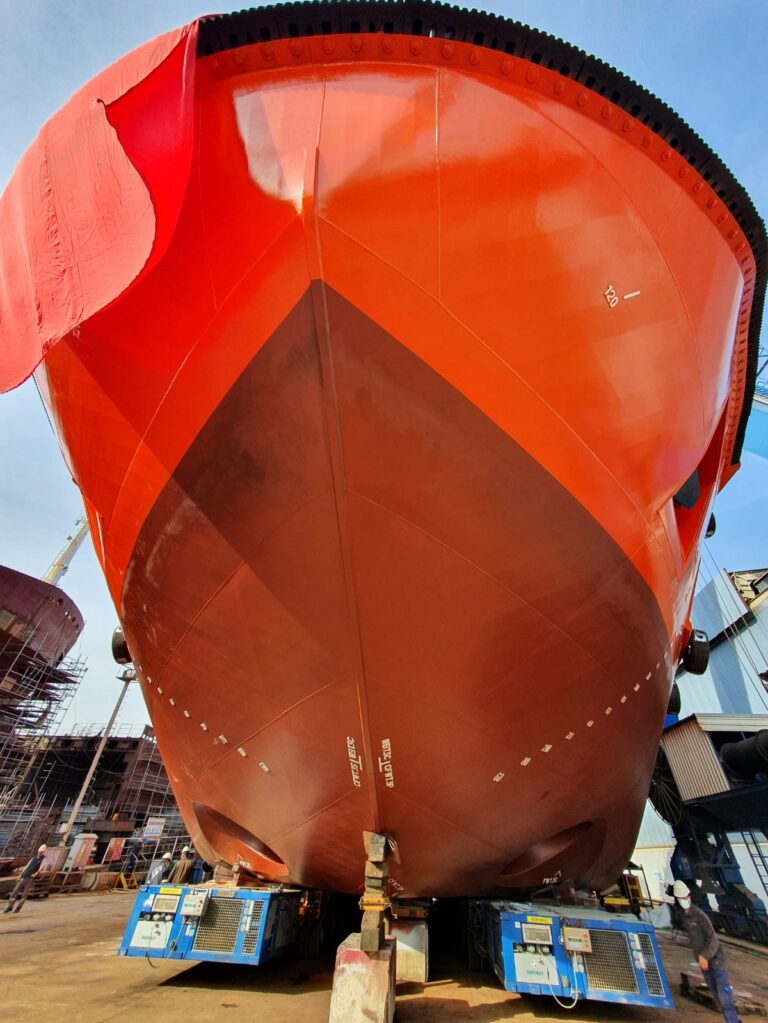

MZ: My experience with Subsea Industries goes back to October 2019. Most often these are periodic drydock inspections in various parts of Europe. They include a number of full hull applications of Ecospeed as well as rudder and azipod Ecoshield and Ecofix applications.

SI: What is your overall impression of Ecospeed as a hull coating, particularly in comparison to other coatings you have inspected?

MZ: In an era of tightening environmental protection regulations, Ecospeed stands out as a high wear resistant, non-toxic, 2-coating system which complies with the requirements of anti-fouling systems as stated in (AFS/CONF/26). Its performance warranty makes it a product which is increasingly chosen for projects.

“In an era of tightening environmental protection regulations, Ecospeed stands out as a high wear resistant, non-toxic, 2-coating system.”

SI: How do you feel about Ecoshield and Ecofix as a solution for the repair of rudders and running gear that has been damaged by cavitation and corrosion, and as protection against damage from cavitation, corrosion.

MZ: Ecofix is a proven, effective and timesaving filler which provides extraordinary protection against cavitation damage. By using the same basic resin as Ecoshield it is very economical and becomes a very competitive alternative to expensive surfacing of steel by welding. I am not sure if I can compare Ecofix to other fillers used in the market. But, as far as I have observed, the consistency of Ecofix significantly increases the efficiency of the application that restores the steel back to its original shape with a smooth surface.

SI: How easy and quick is the application? Does it save time compared to other alternative products?

MZ: If you stick strictly to the application requirements, the 2-coating system provides good hull protection and mechanical anti-fouling properties and facilitates a flexible application schedule. Because of the very short and no maximum overcoat time, we can accomplish fast painting up to 100 liters within a 30 minutes window when applying it to the exterior hull structure.

SI: How is your relationship with Subsea Industries as a company you do work for?

MZ: Providing service for Subsea Industries is an especially valuable cooperation since I am working with a different concept of hull coatings which has set a new trend. They provide a high standard of technical support with immediate assistance, leading all parties involved to a successful project.

SI: How would you sum it all up?

MZ: Subsea Industries offers products that sell themselves.

“Subsea Industries provides a high standard of technical support with immediate assistance, leading all parties involved to a successful project.”

“Subsea Industries offers products that sell themselves.”

Mehmet Acer

Mehmet Acer is an Independent Paint Inspector based in Istanbul, Turkey. Having graduated in 2002 with a degree in naval architecture and marine engineering, Mehmet went to work as a paint inspector. In 2008 he achieved FROSIO 3 certification. His twenty years in the industry as an inspector have brought him into contact with many different brands and types of coating. He specializes mostly in marine coatings and has represented Subsea Industries on about ten Ecospeed and/or Ecoshield applications.

Mehmet Acer is an Independent Paint Inspector based in Istanbul, Turkey. Having graduated in 2002 with a degree in naval architecture and marine engineering, Mehmet went to work as a paint inspector. In 2008 he achieved FROSIO 3 certification. His twenty years in the industry as an inspector have brought him into contact with many different brands and types of coating. He specializes mostly in marine coatings and has represented Subsea Industries on about ten Ecospeed and/or Ecoshield applications.

SI: What is your overall impression of Ecospeed as a hull coating, particularly in comparison to other coatings you have inspected?

MA: No limitation for overcoating is one of the most important advantages. Additionally, fast drying, easier adjustable catalyst (1 to 2 percent), and the fact that it is applicable at higher thickness (500 to 1500 microns) without sagging or running are all advantages. The only disadvantage is that more roughness is required for surface preparation compared to other products.

“No limitation for overcoating is one of the most important advantages.”

SI: What is your opinion of Ecoshield and Ecofix as a solution for the repair of rudders and running gear?

MA: They offer excellent protection against cavitation and corrosion and require less repair compared to other products.

SI: How easy and quick is the application?

MA: It’s a big advantage that it consists entirely of two layers with extended overcoating interval. It is fast drying which makes it possible to complete the application on the same day. The fact that there is less possibility of sagging or running at high thickness saves time with less repairs. The fact that cans of 1 and 4 liters are available saves waste on minor repairs.

Mehmet describes the relationship with Subsea Industries as “Honest!!!”

Conclusion

These are two more of the network of independent paint inspectors who attend applications of Ecospeed and Ecoshield to assist with providing the advice and guidance needed to ensure that the coatings are standardly applied and meet all the requirements.

We will be interviewing others in the future and hope that the information they share is helpful in providing a comprehensive picture of our coatings and some comparison with other coatings that these inspectors come into regular contact with.