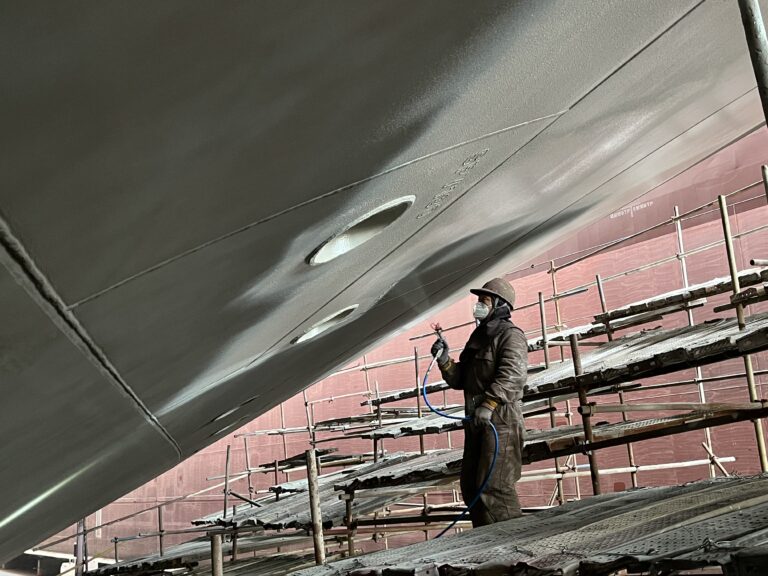

Over the last year our Ecospeed coating system was applied on the scrubber pipes, outlets and diffusers of over 30 vessels. This demonstrates that Ecospeed is not only the best option for the underwater hull of a ship but can also be used for a wide range of other purposes. The result is a lasting, non-toxic protection against corrosion, cavitation and mechanical damage.

Because of the tight regulations on emissions in the shipping industry, the installation of an exhaust scrubber system has become increasingly widespread. This unfortunately has also led to an increase of corrosion damage on scrubber pipes and outlets which results in water ingress in the engine room, ballast tanks and cargo holds.

Ecospeed however is highly chemically resistant. Using the coating to protect the exterior outlets as well as the interiors of scrubbers will prevent corrosion damage and the resulting consequences.

Ecospeed fits in seamlessly with the environmental idea behind scrubber systems. It is a lasting, chemically resistant coating that will withstand the hazardous pollutants and protect the scrubbers for the lifetime of the vessel.

Fixing corroded pipes

If an existing scrubber suffers corrosion damage, it is not too late to fix it. Subsea Industries’ sister company Hydrex regularly replaces scrubber overboard pipes. This is done on-site without the ship needing to go to drydock.

In all cases the new pipes are protected with Ecospeed. If no welding work needs to be carried out in close proximity to the coated area, the new pipes are coated in advance. If this is not an option, Ecospeed is applied after the new pipe is installed.

Pipes can also be replaced preemptively. If a pipe starts to corrode, a leak is just a matter of time. By performing the replacement before the leak occurs, a costly, unscheduled repair can be avoided.

Conclusion

Several benefits make Ecospeed the perfect choice to protect scrubbers.

- The coating system is highly chemically resistant. Taking into account the nature of the process taking place inside the scrubber, this is essential for our customers.

- Ecospeed lasts the lifetime of a vessel. No repaints will need to be scheduled during future dockings of the ship. This saves time and money.

- It is a true biocide-free solution. The coating is 100% toxin-free and that there is no negative effect on the water quality or the marine environment at any point of its application or use.

Over the last year our Ecospeed coating system was applied on the scrubber pipes, outlets and diffusers of over 30 vessels. This demonstrates that Ecospeed is not only the best option for the underwater hull of a ship but can also be used for a wide range of other purposes. The result is a lasting, non-toxic protection against corrosion, cavitation and mechanical damage.

Because of the tight regulations on emissions in the shipping industry, the installation of an exhaust scrubber system has become increasingly widespread. This unfortunately has also led to an increase of corrosion damage on scrubber pipes and outlets which results in water ingress in the engine room, ballast tanks and cargo holds.

Ecospeed however is highly chemically resistant. Using the coating to protect the exterior outlets as well as the interiors of scrubbers will prevent corrosion damage and the resulting consequences.

Ecospeed fits in seamlessly with the environmental idea behind scrubber systems. It is a lasting, chemically resistant coating that will withstand the hazardous pollutants and protect the scrubbers for the lifetime of the vessel.

Fixing corroded pipes

If an existing scrubber suffers corrosion damage, it is not too late to fix it. Subsea Industries’ sister company Hydrex regularly replaces scrubber overboard pipes. This is done on-site without the ship needing to go to drydock.

In all cases the new pipes are protected with Ecospeed. If no welding work needs to be carried out in close proximity to the coated area, the new pipes are coated in advance. If this is not an option, Ecospeed is applied after the new pipe is installed.

Pipes can also be replaced preemptively. If a pipe starts to corrode, a leak is just a matter of time. By performing the replacement before the leak occurs, a costly, unscheduled repair can be avoided.

Conclusion

Several benefits make Ecospeed the perfect choice to protect scrubbers.

- The coating system is highly chemically resistant. Taking into account the nature of the process taking place inside the scrubber, this is essential for our customers.

- Ecospeed lasts the lifetime of a vessel. No repaints will need to be scheduled during future dockings of the ship. This saves time and money.

- It is a true biocide-free solution. The coating is 100% toxin-free and that there is no negative effect on the water quality or the marine environment at any point of its application or use.