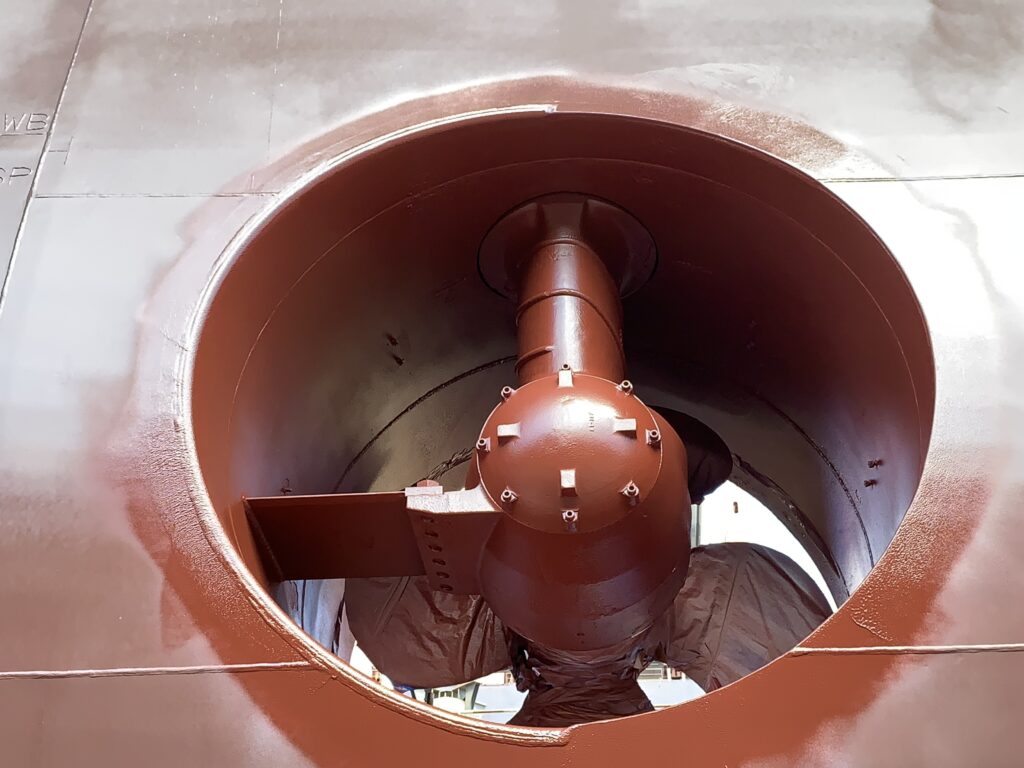

Besides offering rudder protection, Ecoshield is also suitable for all underwater ship gear which needs special protection from corrosion. The extra strength coating protects these areas for the service life of the ship. Good examples of this are the many thruster tunnels which have been coated with Ecoshield with great success.

In most cases companies begin by coating one rudder experimentally, only to go on and order Ecoshield for all the running gear in their fleet after seeing the results in service.

Grit blasting, and application of the two layers is always done in the presence of one of our inspectors. The timing is geared to the schedule of the yard. This flexibility can be easily achieved with Ecoshield because the coating has a minimum overcoating time of only three hours, and no maximum. This allows for the possibility of applying either of the two required layers at any time during the building process.

Ecoshield has been tested on running gear since 2002 with extraordinary results. Ships that were experiencing heavy cavitation damage to their running gear have seen no further cavitation damage erosion. Some of them have been sailing for well over 15 years after application with no sign that the coating will need replacement.