(Important Note: This article may not be republished or reproduced in any form without the explicit, in-writing permission of Subsea Industries NV.)

In April 2021, Fednav’s Umiak I, one of the world’s most powerful icebreaking cargo ships, had the entire hull from keel to gunnel coated with Ecospeed Ice, replacing the existing hull coating.

So, more than two years of heavy icebreaking later, how is the coating holding up?

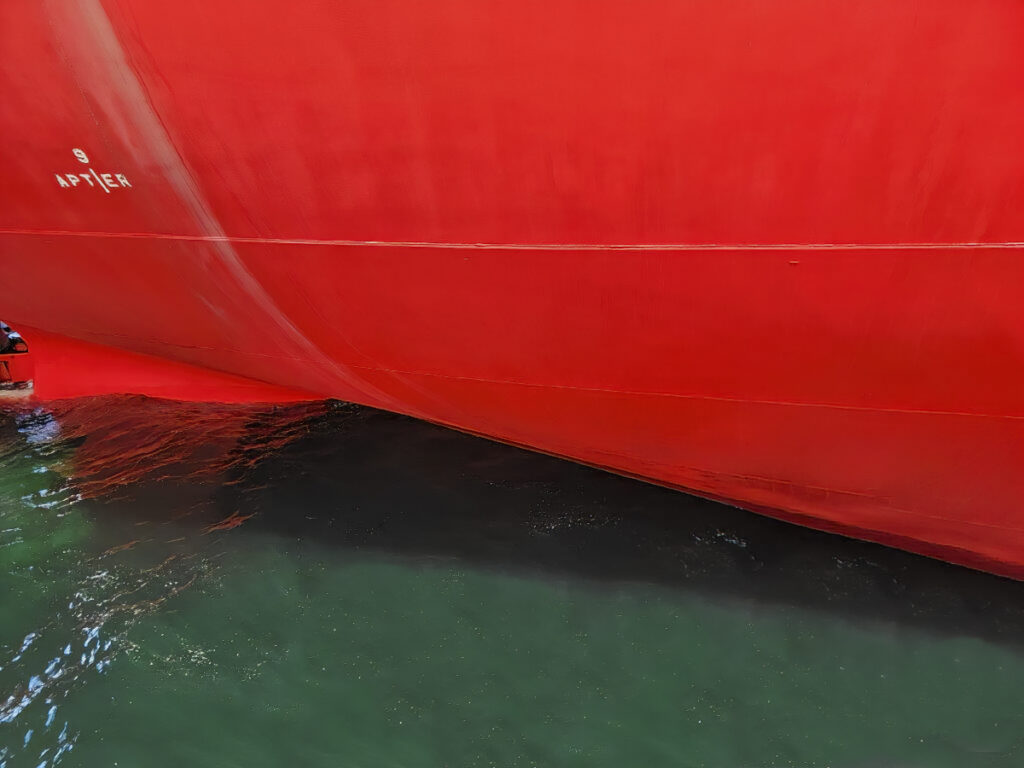

Craig Verge, the superintendent of the Umiak I says, “I was out and had a look at the hull coating in Long Harbor, [near St. John’s in Newfoundland & Labrador, Canada].” Craig works for Canship Ugland Ltd., the St. John’s N.L. based ship management company that manages a variety of vessels including this 189-meter icebreaking bulk carrier. “The Ecospeed is holding up well – as far as I can see there does not appear to be any damage from ice whatsoever,” he says, “There is also only minimal mechanical damage from chains on fenders and tugs, and marks from tires.” This report is from August 2023, more than two full years of service since the ship’s hull coating was changed to Ecospeed Ice.

Fednav Ltd

The Umiak I is owned by Fednav Limited. With more than 75 years in the international shipping business, Montreal-based Fednav Limited is Canada’s largest ocean-going, dry-bulk shipowning and chartering group.

Fednav’s maritime freight division annually transports over 30 million tons of mainly dry–bulk, including agricultural products, sugar, fertilizers, and industrial minerals as well as steel and other general cargo on their fleet of 120 owned and chartered vessels.

The fleet is comprised of Handysize, Supramax, and Ultramax bulk carriers. Renowned for Arctic trading expertise, Fednav boasts the world’s largest fleet of ice-class bulk vessels.

Specializing for six decades in the St. Lawrence-Great Lakes Seaway System and in the ice-covered waters of the Arctic, today, Fednav’s wider focus is on the transportation of bulk and breakbulk on a worldwide basis.

Having participated in every major shipping project in the Canadian Arctic since the late 1950s, Fednav’s Arctic Operations department knows how to deliver innovative and effective solutions for that challenging region.

The company owns and operates both 31,500-tonne MV Umiak I and MV Nunavik, the most powerful icebreaking bulk carriers of their kind as well as the MV Arvik I, an icebreaking vessel powerful enough to navigate unescorted through ice-covered waters. Fednav knows ice!

MV Umiak I

Built in Japan at the Universal Shipbuilding Corporation’s Maizuru shipyard, the Umiak I was delivered in 2006. At the time it was the highest ice-class, non-nuclear cargo vessel in the world with DNV ICE-15 classification. “Umiak” is the native Inuktitut name for a supply boat. The ship was purpose-built to transport nickel ore from the Voisey’s Bay mine in Labrador, Canada to the Long Harbour Nickel Processing Plant on Newfoundland’s south coast. Umiak I makes twelve trips per year, transporting a total of 360,000 tonnes of nickel concentrate worth 1.5 billion CAD. On the return trip, the ice-breaking cargo ship carries re-supply cargoes for the Voisey’s Bay mine.

The Umiak I’s main engine is coupled directly to a ducted controllable-pitch propeller. The variable-pitch propeller allows backing and ramming in heavy ice conditions without reversing the engine, and the nozzle protects it from ice impacts and provides additional thrust. In open water, Umiak I can achieve a speed of 13.5 knots (25.0 km/h; 15.5 mph) with only 35% engine load. In 1.5-metre (5 ft) ice, she can maintain a speed of 3 knots (5.6 km/h; 3.5 mph) with the aid of a water deluge system in the bow.

Deservedly, the Umiak I was the star of the 5th episode in Season 5 of “Mighty Ships,” a documentary television program aired on Discovery Channel Canada in August 2011. She is indeed a mighty ship.

Umiak I and Ecospeed Ice

As can be expected, the hull coating on the Umiak I is subjected to some of the harshest treatment any hull coating can receive. The original coating was not holding up as well as desired. Thus it was that in the ship’s 2016 drydocking, it was decided to apply two test patches of Ecospeed Ice, a coating that had been very successful in other ice applications including the British Antarctic Survey’s Antarctic research and supply vessel, the RSS Ernest Shackleton.

For the next five winter seasons, the test patches were closely monitored and found to be holding up remarkably well.

Based on the success of the test patches, in early 2021 it was decided to replace the Umiak I’s entire hull coating with Ecospeed Ice. The application was carried out in Remontowa Shiprepair Yard in Gdansk, Poland.

Where the steel had been severely pitted from ice-abrasion, particularly on the bow and the nozzle, the surface was first repaired with Ecofix, a compatible filler designed for use with Subsea Industries coatings. Ecospeed can be applied over Ecofix with only a one-hour overcoat time which can save a great deal of time in the yard.

(the article continues after the pictures)

Results to date

The Umiak I maintained its regular schedule for the next two years, forcing its way through heavy ice up and down the Labrador coast carrying its valuable cargo in the usual harsh conditions.

It was in July 2023, over two years after the Ecospeed Ice application, that the ship’s superintendent, Craig Verge inspected and photographed the hull when the ship was moored at Long Harbour. The photos confirm his report that the hull coating had suffered no ice damage whatsoever.

Craig says, “The crew did report some minor coating damage from ice on the leading edge of the nozzle.” This is not surprising considering the role the nozzle plays in the repeated backing and ramming operation the ship employs to make its way through heavy ice. However, the nature of Ecospeed prevents undercreep and is also very easy to repair in drydock since it is one homogenous coating rather than a complex scheme of different types of paint. The repair blends in perfectly with the original hull coating.

(the article continues after the pictures)

Conclusion

David Williams, Senior Manager, Technical Services Fleet Management at Fednav was the naval architect responsible for introducing Ecospeed Ice to the company and initiating the test patches applied at the Verreault shipyard in Quebec in 2016.

Looking back on that decision, in light of the results shown by the recent inspection after two years of the Umiak I’s sailing with Ecospeed Ice, David Williams says: “Fednav has operational experience with various ice resistant hull coatings over our history as owners and operators of ice class vessels. Service experience with Ecospeed test patches, and later a full application of Ecospeed, on the Umiak I has demonstrated to us that Ecospeed is the leading hull coating product, of those we have tested, for this application.”