Eeva VG – First of two energy efficient dry cargo vessels coated with Ecospeed

At the end of January the application of newbuild m/s Eeva VG with Ecospeed was finalized. The vessel is the first of two very energy efficient dry cargo carriers managed by VG-Shipping. They will operate in the Baltic region.

Both ships are VG EcoCoasters. They are owned by Meriaura Group of which VG-shipping is a part. The vessels were designed as a new ship concept by Meriaura together with its partners Foreship Ltd and Aker Arctic Technology Inc.

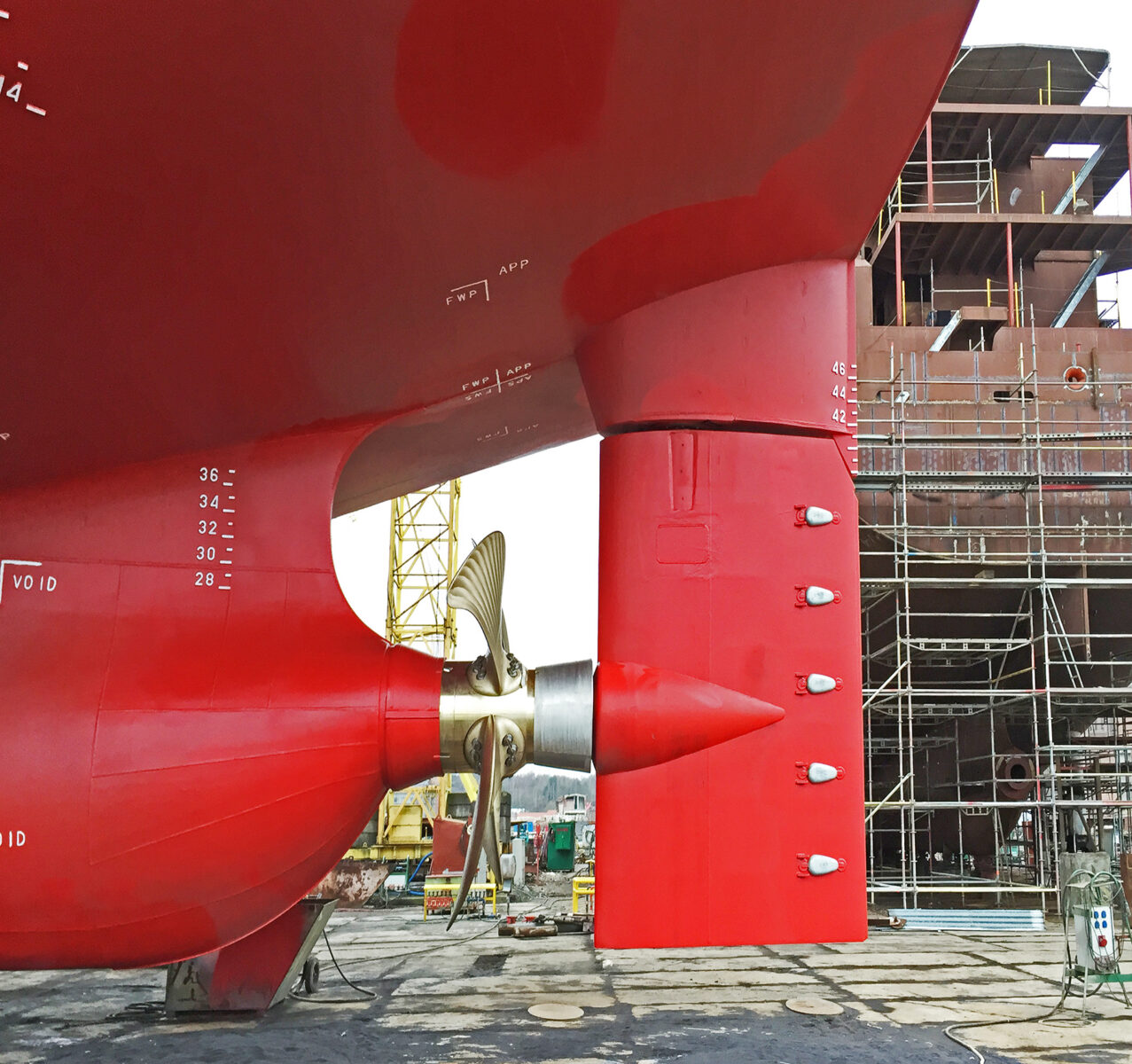

VG EcoCoasters are designed to cause considerably less environmental impact than conventional dry cargo vessels. The hull and machinery of the newbuildings are optimized to the speed of 10,5 knots in open water conditions. Power required for Ice Class 1A is achieved by a diesel electric driven booster unit. The aim is to almost halve the fuel consumption compared to conventional dry cargo vessels of similar type and size, and therefore also cut emissions remarkably. The ships are capable of using alternative biofuels produced in VG-Shipping’s own refinery located in Uusikaupunki, Finland. The new vessels will meet all the maritime environmental regulations coming into force in the next few years and in many cases will even exceed them.

Meriaura Group entered into a contract with Dutch shipyard Royal Bodewes for the building of the vessels. M/s Eeva VG was launched on February 5th 2016 with delivery at the end of July. The second vessel is expected to follow in the autumn of 2016.

VG EcoCoasters are designed to cause considerably less environmental impact than conventional dry cargo vessels.

An energy efficient coating for an energy efficient vessel

One major cruise line has been quoted as saying that they are saving 20% on fuel costs with Ecospeed compared to the earlier TBT coating which they replaced. Another owner found that they gained 3 knots over sea trials speed when they replaced their hull coating with Ecospeed.

“We didn’t want to use a traditional antifouling system because of the chemicals that they contain and found the Ecospeed solution was the most effective coating system for reducing drag.

VG-Shipping applies Ecospeed to second EcoCoaster

Following the success of the Eeva VG, VG-Shipping, the ship management arm of the Meriaura Group selected Subsea Industries’ non-toxic Ecospeed hull coating for its second environmentally-safe cargo ship newbuild.

The Royal Bodewes built Mirva VG joined the first of class Eeva VG, which will be delivered in September following outfitting in Papenburg, Germany. The vessels are owned by Gaiamare Oy, a Meriaura Group company.

Both 4700dwt EcoCoasters have now been coated with the game-changing Ecospeed hard coating above and below the water line in VG Shipping’s red and blue livery.

Ismo Saaros, Director, Project Management, VG-Shipping, explained: “We wanted to produce the cleanest, most environmentally-efficient coasters of their class so we specified several ‘green’ solutions, including a ballast water management system, a Selective Catalytic Reduction system for reducing NOx emissions and the Ecospeed hull coating.“We didn’t want to use a traditional antifouling system because of the chemicals that they contain and found the Ecospeed solution was the most effective coating system for reducing drag. With a hard coating we are also permitted to clean the hull underwater in the ports where we operate without damaging its waters and sediments.”

The environmental and hard-wearing performance of the coating was also and aspect flagged up by Robert Jan Steenbergen, Project Manager at Royal Bodewes.

He said: “Since Ecospeed is not a biocide-containing antifouling it is more environmentally-friendly and because these vessels will operate in the Baltic we needed a coating suitable for sailing in ice. It lasts longer.”

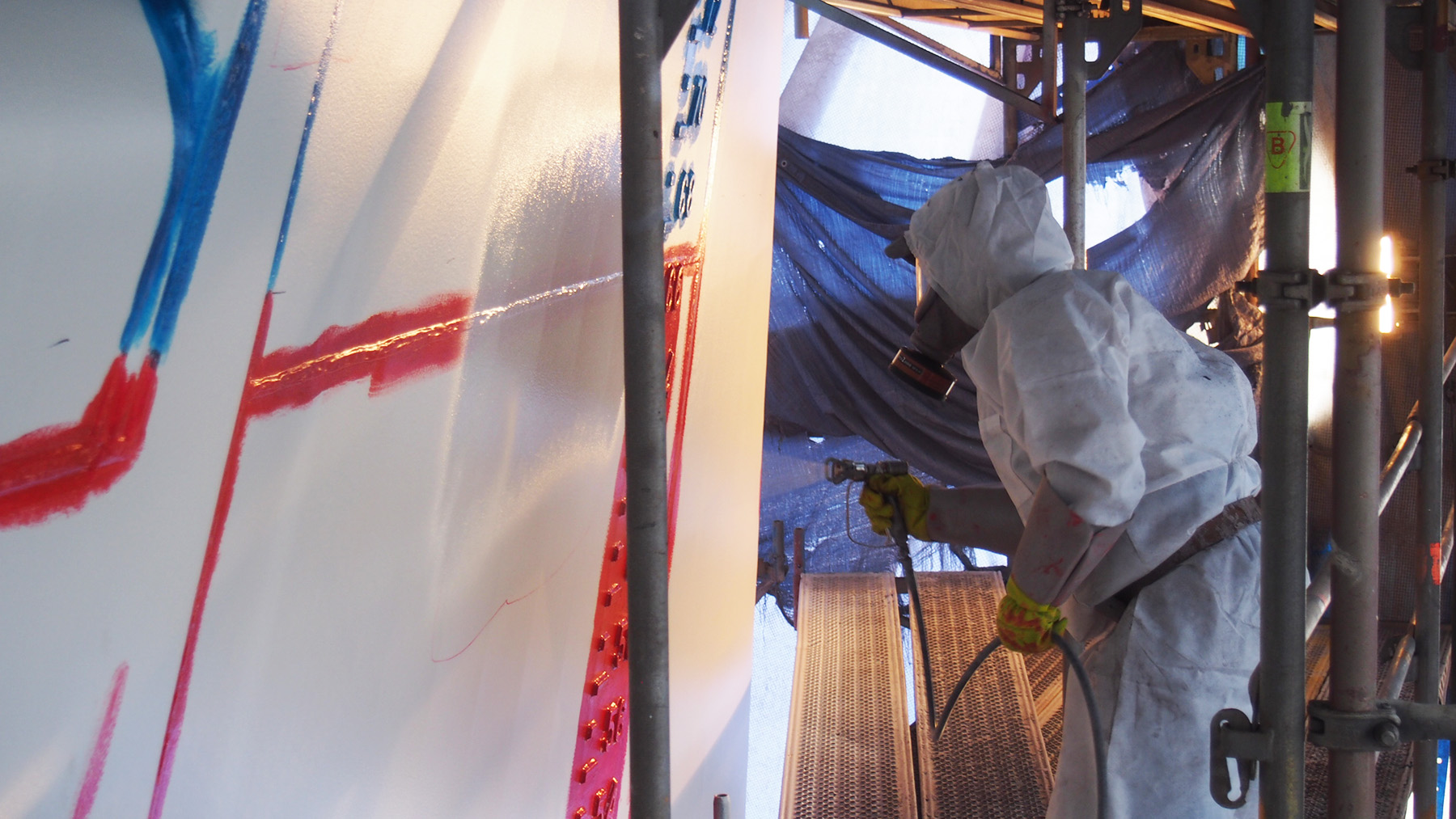

Ease of application

Commenting on the application of the coating, Steenbergen, added: “It was the first time the yard had applied Ecospeed on this scale, to a complete hull, but application was very straightforward.

“Applied under Subsea Industries’ supervision, the result is very good: the preparation, the blasting and how it looks gives us confidence that this coating will perform exceptionally well.”

Built to the ‘Cleanship’ class notation, the VG EcoCoasters, designed by Finland’s Foreship and Aker Arctic, are part of a fleet expansion programme to strengthen Meriaura Group’s position in the market for vessels of this class.

Each vessel features a hull form, systems and technologies designed to substantially reduce the impact of operations on the marine environment.

The vessels propulsion arrangement, which incorporates a power take-in booster system to reach ice class engine power, has been optimised for slow steaming operations at speeds between 8 and 9kts, although main engines can attain a top speed of 10.5kts in open water conditions. The fuel-efficient ice-class 1A vessels are powered by an ABC 8DZC dual-fuel engine, capable of running on marine gas oil (MGO) and biofuel produced at Meriaura Group’s refinery in Uusikaupunki.

“Applied under Subsea Industries’ supervision, the result is very good: the preparation, the blasting and how it looks gives us confidence that this coating will perform exceptionally well.”

Advantages of Ecospeed

Manuel Hof, Production Executive and NACE Coatings Inspector at Subsea Industries, said: “We are delighted to have added to VG-Shipping’s exceptionally ‘green’ cargo vessels with our Ecospeed coatings. VG-Shipping specified Ecospeed at the design stage because of the coating system’s proven performance.

“Mirva and Eeva will not have to be coated again during the vessels’ operational lifetime, saving the company thousands in paint costs and drydocking fees, whilst preventing damage to the marine environment through the emissions of toxic chemicals found in conventional soft coatings.”

Subsea Industries Executive Director Boud Van Rompay added: “With these vessels operating in arctic waters, the owner required a coating capable of withstanding ice impact and highly abrasive waters. Polar trading is one of the biggest challenges for coatings manufacturers, since abrasive waters scratch and scrape conventional anti-fouling paints resulting in hull recoats after just one season. Subsea Industries’ hard coatings are developed to last even in the harshest of environments.”

Referring to Interscan Schiffahrt’s 3000dwt ice-class cargo vessel Patriot, which was coated with Ecospeed in 2005 after the owner found its traditional hull coating was lasting just two seasons, Van Rompay revealed that after ten years’ ice operation the Ecospeed hull coating remained intact. “When Patriot drydocked in 2015, besides some minor mechanical damage which was easily touched up, the coating was immaculate.”

“Mirva and Eeva will not have to be coated again during the vessels’ operational lifetime, saving the company thousands in paint costs and drydocking fees…”

Five years later...

Ecospeed in excellent conditions after 5 years in ice

When the 4700dwt Eeva VG docked in Naantali, Finland in June 2021, the Ecospeed coating on its hull was still in excellent condition. The ship was coated at the start of 2016. During this most recent docking only very minor touch-ups were needed, despite the severe ice conditions the ship has encountered.With these vessels operating in arctic waters, the owner requires a coating capable of withstanding ice impact. Polar trading is one of the biggest challenges for coatings manufacturers, since abrasive waters scratch and scrape conventional anti-fouling paints resulting in hull recoats after just one season. Subsea Industries’ hard coatings are developed to last even in the harshest of environments.

An ice-going hull coating must also have low friction characteristics in order to be fuel efficient. But it is not enough for the hull to be smooth and have low friction at launch. It must stay that way for the life of the vessel. Ecospeed will hold up and will not be damaged in the ice and so will remain smooth for the life of the vessel, thus saving fuel. Even if minor repairs are needed in drydock the original quality of the coating remains intact.

150 ice going hulls, including the newbuild research vessel RRS Sir David Attenborough, have been coated with our products with great and conclusive results. This shows that they can withstand the impact of ice for many years on end.