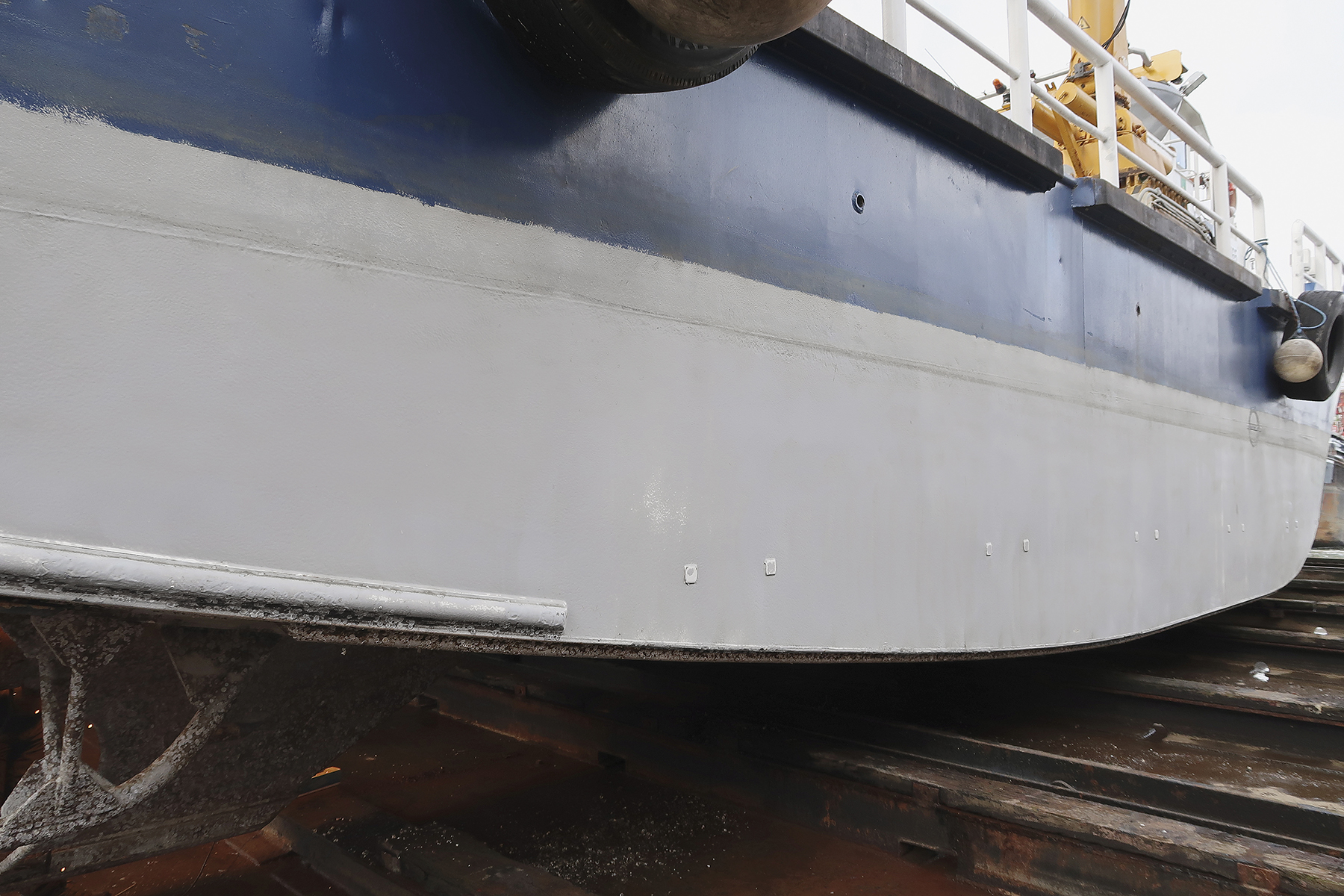

Ten years after Ecospeed was applied on two of the Hydrex workboats, one of them docked in Antwerp. The coating was still in near-perfect condition and no repaint or touch-ups were required.

For the Hydrex divers that regularly clean the workboats this came as no surprise. “When we clean the hulls, the surrounding water remains clean. Only fouling is washed off the vessel,” said one of them. “Inspecting the hull of the vessel underwater always shows the pristine condition of Ecospeed. This is in sharp contrast with the regular anti-fouling coatings on other underwater hulls we see.”

Subsea Industries’ Executive Director Boud Van Rompay explained: “With Ecospeed there is no need to reblast and recoat the hull; no chance of corrosion, no impact on the environment and, if regular hull cleaning is carried out, large fuel savings can be achieved.”

“With Ecospeed there is no need to reblast and recoat the hull; no chance of corrosion, no impact on the environment and, if regular hull cleaning is carried out, large fuel savings can be achieved.”

The hull of one of the Hydrex workboats in drydock 10 years after Ecospeed was applied, with no repainting during that interval.

“Vessels coated with Ecospeed can be cleaned effortlessly and legally in ports such as Rotterdam, which have banned the underwater hull cleaning of conventional hull coatings. There is zero environmental impact. The simplicity of cleaning hulls protected with our Ecospeed hard coating system allow Hydrex divers to clean our workboats in just two hours. They use our specially-designed tools and equipment,” said Van Rompay.

Ecospeed is not a foul-release paint but a coating system that requires a completely different, more cost-effective and environmentally acceptable approach to hull protection and anti-fouling. When Ecospeed is cleaned there is no paint loss and no toxic plumes are emitted to contaminate marine life and sediments.

Paint degradation is typical of traditional marine hull coatings, resulting in the need for reblasts and recoats more or less every time the vessel docks. This is costing shipowners dearly and is completely unnecessary.

Ecospeed requires just two coats with a curing time of three hours between each one. A typical soft paint, however, requires four to five coats with a curing time of 12 hours between each.

Boud Van Rompay concludes: “We all have an environmental interest in what is happening in the water. It is therefore very important that we can clean Ecospeed hulls in water very quickly and without damage to the marine environment. Ecospeed is the only sustainable solution for protecting ship hulls.”