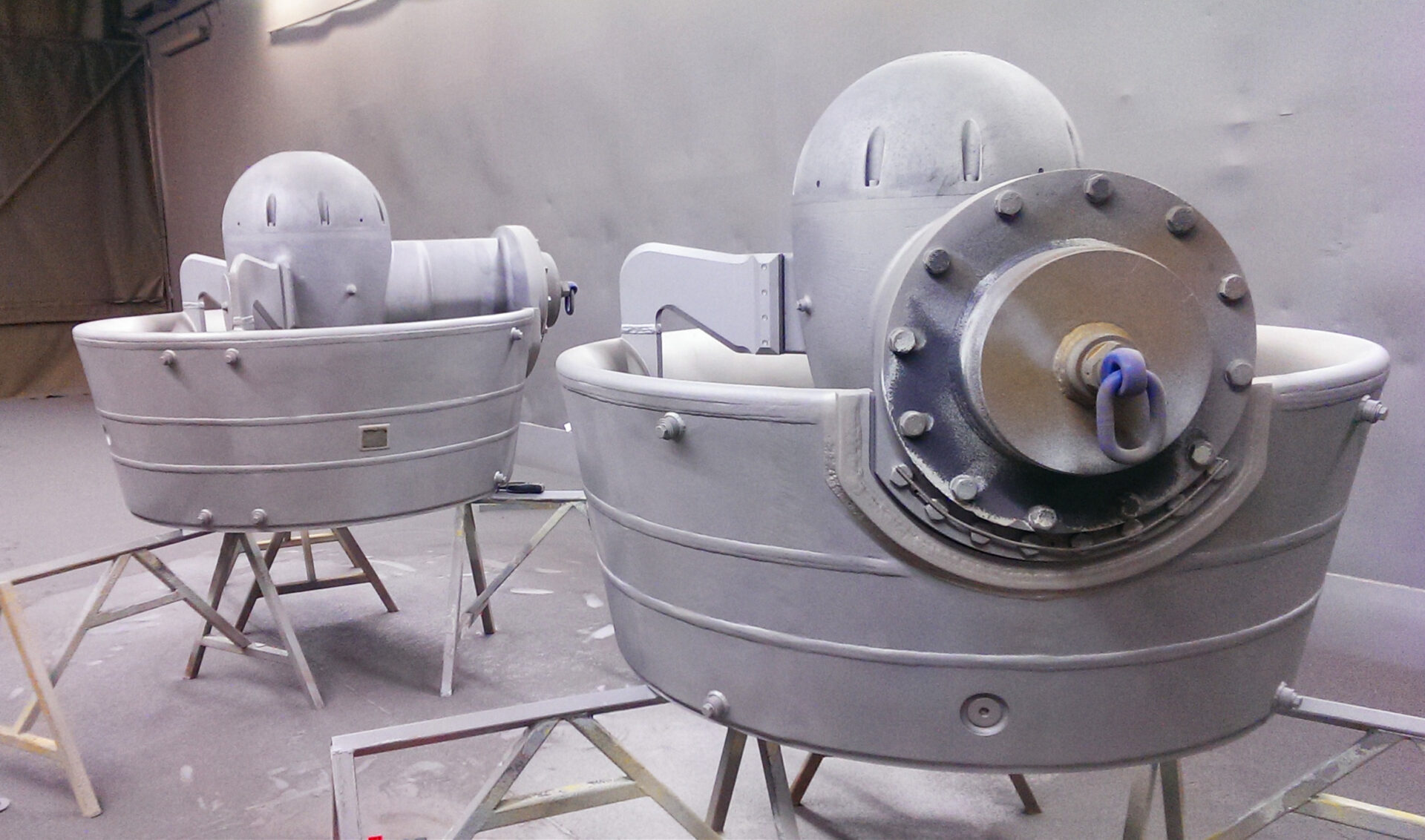

New ZF thrusters with two coats of Ecoshield for lifetime protection.

ZF Marine Krimpen is applying Subsea Industries’ Ecoshield hard coating to the nozzles and underwater components of its azimuth thruster units supplied to vessels operating in inland waterways.

The Netherlands-based company, a division of Germany’s ZF Group, is using Ecoshield on thrusters supplied to a number of US-based customers to reduce operational wear and tear in brown waters such as the Mississippi River.

Since 1973, ZF Marine Krimpen has been designing and producing a wide range of steerable and transverse thrusters, covering a power range between 100 and 2,000 kW, for all types of applications throughout the marine industry. The company shares its parent company’s reputation for providing high quality products and excellent aftersales service. In the past years it has proven more than capable of meeting and exceeding the expectations of its wider partner and is set to make further waves as it thrusts forward into the future.

Frank van der Vegt, Area Sales Manager, Commercial Craft Thruster Systems, ZF Marine, explained: “We were looking to improve the protection of the thruster’s underwater components against damages due to the debris, sand and silt common in shallow draught inland waterways, particularly the Mississippi, as well as to prevent damage due to cavitation and corrosion.”

“We were looking to improve the protection of the thruster’s underwater components against damage due to the debris, sand and silt… as well as to prevent damage due to cavitation and corrosion.”

The solution – Ecoshield

The solution was found in Antwerp, in 2015, when ZF approached Subsea Industries to investigate whether its hard-coating could protect its thrusters from the effects of abrasive waters.

After a series of patch tests proved successful, ZF Marine began applying the hard-coating to all underwater areas of the thruster. Since then, Ecoshield has been applied to the ZF 1000hp azimuth thrusters installed on 12 tow/pushboats operating in US waters.

“We offer the Ecoshield-coated thruster as an option, but it is a very good solution for increasing the life of thruster installations”

Excellent option for customers

“We offer the Ecoshield-coated thruster as an option, but it is a very good solution for increasing the life of thruster installations aboard tugs and pushboats operating in shallow waters,” said van der Vegt. “We can see a really big improvement. They are less prone to damage, reducing maintenance and operational costs. We see these benefits not only with the towboat application, but also other applications such as harbour tugs and passenger vessels.”

Manuel Hof, Production Executive and NACE Inspector at Subsea Industries, said: “We are pleased that ZF Marine’s decision to apply our award-winning Ecoshield hard coating to its thrusters is paying dividends for its customers. The Ecoshield-coated thruster option adds considerable strength to its position as the leading supplier of propulsion systems to the U.S. pusher boat market.”

Subsea Industries has more than 400 ship references for Ecoshield on rudders but is seeing a marked increase in application to thruster tunnels and gearboxes due to the operational savings it brings.

“We are also seeing an increase in interest from original equipment manufacturers,” said Hof. “Ecoshield safeguards propulsion systems and steering gear against cavitation and corrosion damage throughout the vessel’s service life, which can significantly increase the operational life of rudders and thrusters. We have Ecoshield-coated rudders and thrusters that have not needed recoating after more than five years operating in some of the harshest marine environments.”

“We can see a really big improvement. They are less prone to damage, reducing maintenance and operational costs.”

Share this post