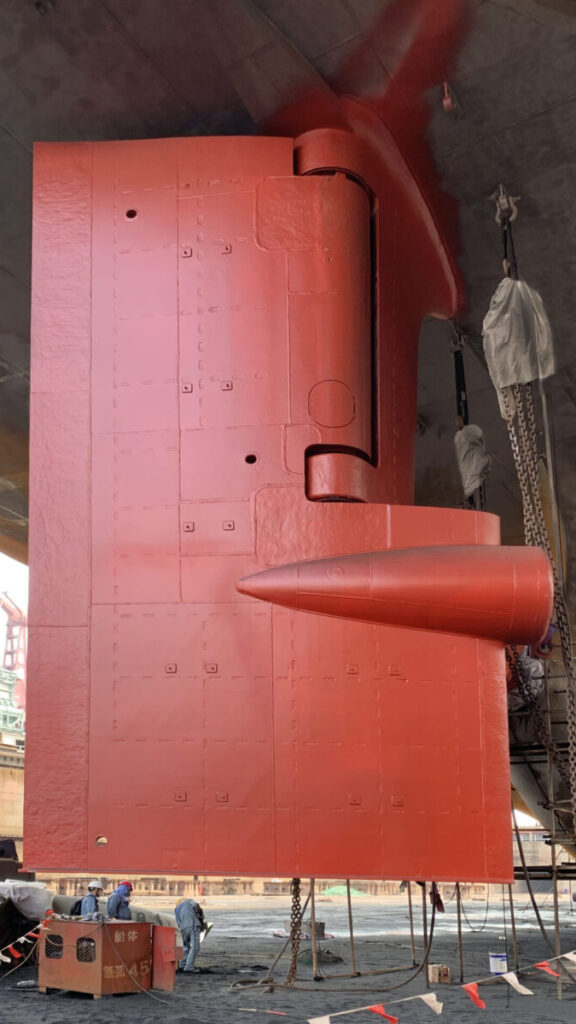

Over the last few months the rudders and running gear of different types of vessels were given an Ecoshield protective coating at yards in France, Turkey, the Netherlands, Finland, Namibia, the U.S.A. and China. These ships include container vessels, roro ships, chemical tankers, a ferry, a tug and an icebreaker.

Most of the ships belonged to different owners. Some of them were new customers, others returning ones. The returning customers had seen firsthand that Ecoshield solved the problem on their other rudders and wanted the same protection for the rest of their fleet. The new ones saw the excellent result obtained by other owners and chose Ecoshield to prevent corrosion and cavitation damage from reoccurring.

Groundbreaking protection

In the last couple of years sister company Hydrex has noted a substantial increase in the number of enquiries for underwater rudder repairs. This clearly shows the need for a cost-saving and lasting solution. A great deal of effort goes into the design and manufacture of rudders because they are such an important part of a vessel. If a rudder is not given the proper protection against cavitation and the resulting erosion and corrosion damage, there can be major financial consequences for the owner.

Ecoshield puts an end to this. By removing the existing paint layers and applying the coating system on running gear we can break the never-ending cycle of painting, suffering damage, having to perform extensive repairs in drydock followed by a full repainting, again and again. Ecoshield gives a very thorough and lasting defense for a ship’s entire service life. No repaint will be required during drydocking. At most minor touch-ups will be needed.

The Ecofix and Ecoshield combo

If a rudder has already suffered corrosion damage, Ecoshield can prevent any further damage from occurring. In such case the coating can be used in combination with another product in the Subsea Industries family: Ecofix.

Ecofix is a superior, tested and proven filler that restores the steel to its original shape with a smooth surface prior to recoating. Because it uses the same basic resin, Ecoshield can be applied just one hour after the filler.

Slot welds can also be filled with Ecofix on a newbuild rudder prior to Ecoshield application.

Ecofix can replace much more costly and time-consuming hot work in most cases.

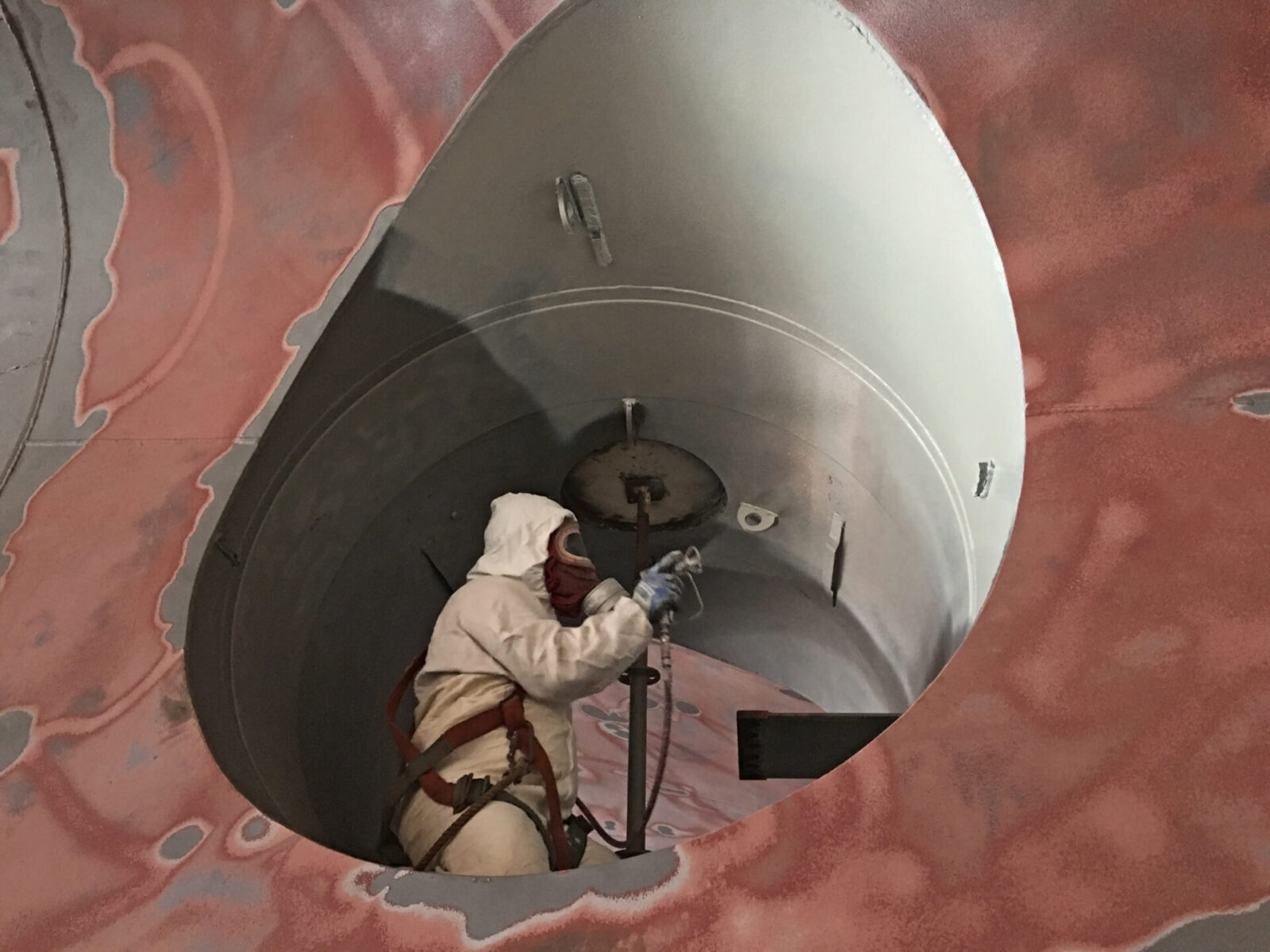

Easy and flexible application

With time at a premium in drydock, the speed of application of Ecoshield is a further advantage. Ecoshield’s flexibility makes it easy to adapt the application schedule to the rest of the activities at the shipyard or drydock in a way which does not interfere with them. Overcoating time can be as short as three hours. With the right planning, grit blasting and application of the two required layers can be performed in just one day.

Suitable for all running gear

Besides offering rudder protection Ecoshield is also suitable for thrusters, azimuth thrusters, azipods, thruster nozzles, thruster tunnels and other underwater ship gear which needs special protection from corrosion. The extra strength coating protects these areas for the service life of the ship. There is no need for recoating or major repair. For this reason several of the vessels treated recently had their thrusters, thruster tunnels or nozzles coated with Ecoshield as well as the rudders.

Results speak for themselves

Evidence of the success of the coating is the number of companies that began by coating one rudder experimentally and have ordered Ecoshield for the running gear on other ships after seeing the results in service. Most have plans to convert their entire fleet. Shipowners who have previously applied Ecoshield to rudders on ships in service are specifying the coating for the rudders and other underwater gear on their newbuilds.

Ecoshield comes with a ten-year guarantee. It is the only coating known to fully protect a rudder from all cavitation damage.

You can give the rudders and running gear of your vessels the same lifelong protection.

Over the last few months the rudders and running gear of different types of vessels were given an Ecoshield protective coating at yards in France, Turkey, the Netherlands, Finland, Namibia, the U.S.A. and China. These ships include container vessels, roro ships, chemical tankers, a ferry, a tug and an icebreaker.

Most of the ships belonged to different owners. Some of them were new customers, others returning ones. The returning customers had seen firsthand that Ecoshield solved the problem on their other rudders and wanted the same protection for the rest of their fleet. The new ones saw the excellent result obtained by other owners and chose Ecoshield to prevent corrosion and cavitation damage from reoccurring.

Groundbreaking protection

In the last couple of years sister company Hydrex has noted a substantial increase in the number of enquiries for underwater rudder repairs. This clearly shows the need for a cost-saving and lasting solution. A great deal of effort goes into the design and manufacture of rudders because they are such an important part of a vessel. If a rudder is not given the proper protection against cavitation and the resulting erosion and corrosion damage, there can be major financial consequences for the owner.

Ecoshield puts an end to this. By removing the existing paint layers and applying the coating system on running gear we can break the never-ending cycle of painting, suffering damage, having to perform extensive repairs in drydock followed by a full repainting, again and again. Ecoshield gives a very thorough and lasting defense for a ship’s entire service life. No repaint will be required during drydocking. At most minor touch-ups will be needed.

The Ecofix and Ecoshield combo

If a rudder has already suffered corrosion damage, Ecoshield can prevent any further damage from occurring. In such case the coating can be used in combination with another product in the Subsea Industries family: Ecofix.

Ecofix is a superior, tested and proven filler that restores the steel to its original shape with a smooth surface prior to recoating. Because it uses the same basic resin, Ecoshield can be applied just one hour after the filler.

Slot welds can also be filled with Ecofix on a newbuild rudder prior to Ecoshield application.

Ecofix can replace much more costly and time-consuming hot work in most cases.

Easy and flexible application

With time at a premium in drydock, the speed of application of Ecoshield is a further advantage. Ecoshield’s flexibility makes it easy to adapt the application schedule to the rest of the activities at the shipyard or drydock in a way which does not interfere with them. Overcoating time can be as short as three hours. With the right planning, grit blasting and application of the two required layers can be performed in just one day.

Suitable for all running gear

Besides offering rudder protection Ecoshield is also suitable for thrusters, azimuth thrusters, azipods, thruster nozzles, thruster tunnels and other underwater ship gear which needs special protection from corrosion. The extra strength coating protects these areas for the service life of the ship. There is no need for recoating or major repair. For this reason several of the vessels treated recently had their thrusters, thruster tunnels or nozzles coated with Ecoshield as well as the rudders.

Results speak for themselves

Evidence of the success of the coating is the number of companies that began by coating one rudder experimentally and have ordered Ecoshield for the running gear on other ships after seeing the results in service. Most have plans to convert their entire fleet. Shipowners who have previously applied Ecoshield to rudders on ships in service are specifying the coating for the rudders and other underwater gear on their newbuilds.

Ecoshield comes with a ten-year guarantee. It is the only coating known to fully protect a rudder from all cavitation damage.

You can give the rudders and running gear of your vessels the same lifelong protection.