The Corrosion Handbook for Shipowners and Operators

A Google search for “corrosion in ships” returned 48,300,000 (forty-eight million three hundred thousand!) results in 0.35 seconds. A search for “books on corrosion of ships” returned 35,800,000 results in the same amount of time. Then there are volumes and volumes of scientific papers, journals, white papers, brochures and advertisements, not to mention podcasts, videos, courses and so on. One would think, with all that vast body of information, that the subject of corrosion at sea would long since have been solved.

And yet, the problem continues to come up and loom heavily in the lives of ship superintendents, fleet managers, ship builders, ship repair yards, chief engineers, vessel captains and many others who are in charge of protecting ships’ hulls and running gear. They are responsible for safety at sea, the continued proper functioning of the ship and the vessel’s maintained value over time. Corrosion is their main enemy.

Subsea Industries successful solutions

At Subsea Industries we manufacture and supply a range of marine coatings, all formulated with the same basic principle: insulate the steel or other substrate completely with a permanent, tough, glass-based coating and there will be no corrosion.

Evidence is piling up. As you can read in the first article in this magazine, major shipping lines are coming back to us again and again, asking us to coat their ships’ rudders, thruster tunnels, nozzles, scrubber outlets and a number of other specific parts which are particularly prone to corrosion, even when they are coated with traditional hull coatings. Why? Because our coatings really do protect their ships from corrosion. They find that they can even dispense with cathodic protection since the coating insulates the steel so completely that galvanic corrosion is prevented. In the editorial of the same magazine this topic is elaborated on.

The Corrosion Handbook

After many years of dealing with these requests successfully, we decided to publish a book written by the company’s founder, Boud Van Rompay: Corrosion Handbook for Shipowners and Operators, The Use of Special Coatings to Protect Specific Parts of Ships from Corrosion.

Unlike many of the other books on the subject, this one is rather slim. It is clearly written in simple English and well illustrated. In its pages you will find the answers to the permanent protection of a number of parts of the ship from corrosion.

Three different types of corrosion are covered:

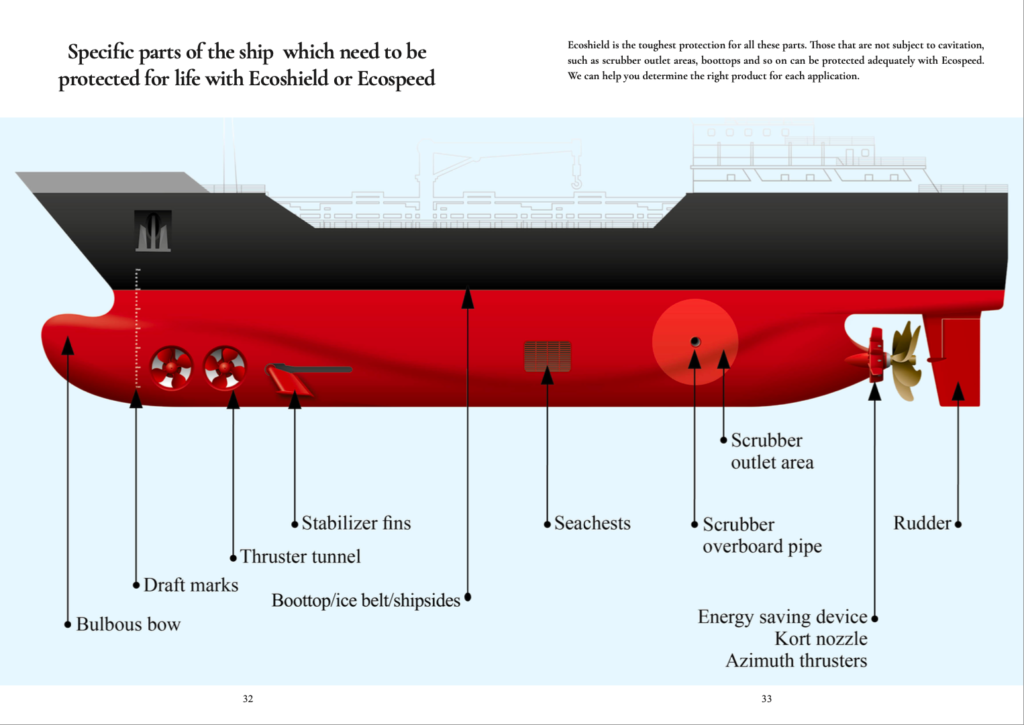

- Cavitation erosion on rudders, in thruster tunnels, nozzles and other cavitation-prone parts of the underwater ship.

- Chemical corrosion in scrubbers, pipes, recycle tanks and scrubber outlet areas.

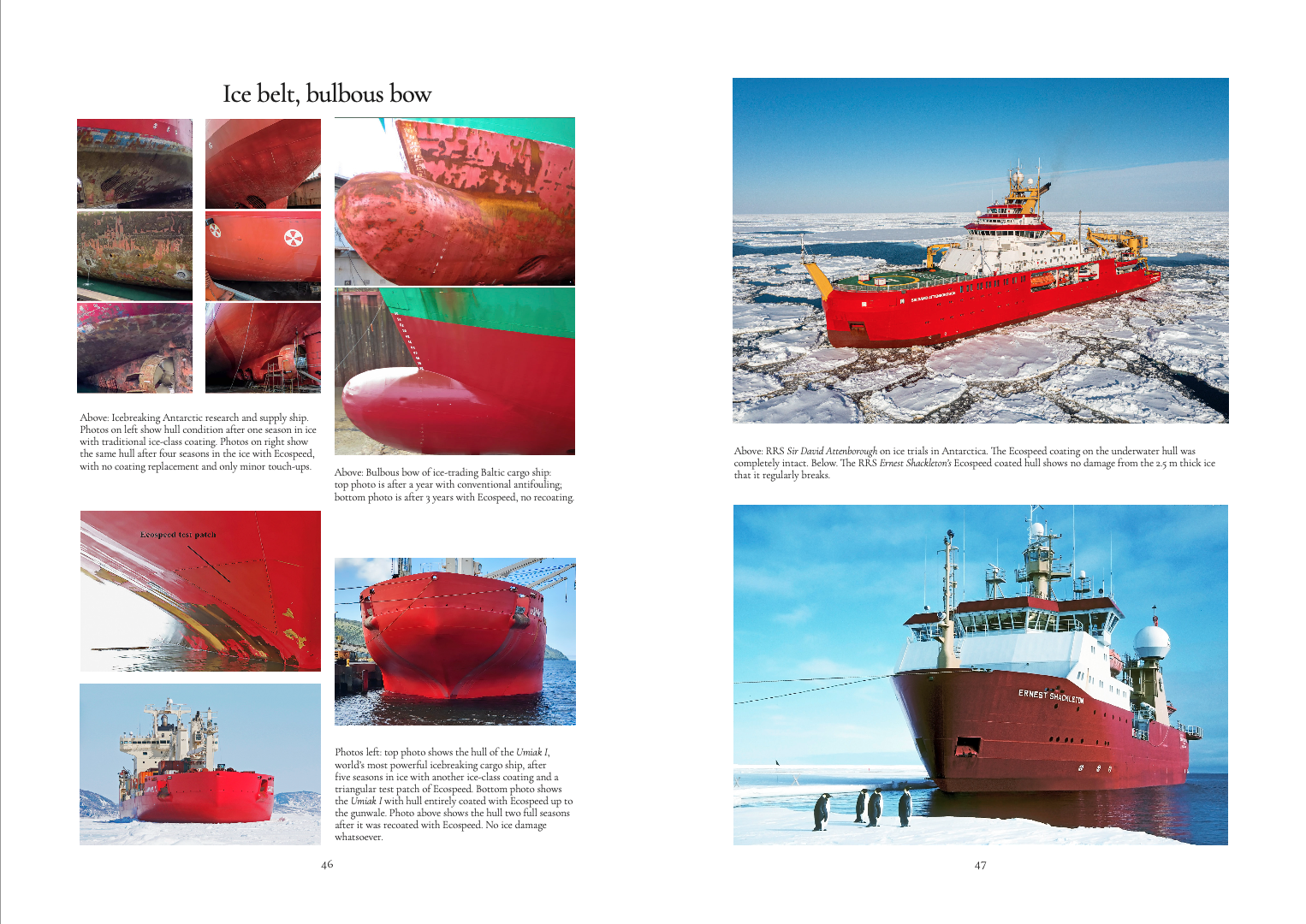

- Impact abrasion and wear on boottops, shipsides, ice belts, bulbous bows, decks, etc.

Why these specific areas? Because these are the parts of ships that we are regularly asked to provide the right coating for. These are the areas with which we have had enormous success, evidenced by the requests from major shipping companies to provide the same treatment for ship after ship in their fleet.

The Corrosion Handbook also covers the protection of high traffic decks, the bulbous bows of ice going vessels, stabilizer fins, unusual items such as the Hull Vanes®, even the hoppers of dredgers. Anywhere where corrosion and erosion resulting from cavitation, chemical action or high impact abrasion is a threat, we have the permanent solution.

The Corrosion Handbook provides in very concise form the exact proven answer to each of these types of corrosion and parts of the ship. It includes many examples showing the workability of the solution and of our coatings.

Apply once, last forever

The book makes it quite clear that Subsea Industries does NOT follow the repeat business model so common in the coatings industry today, where coatings are expected to last a limited period of time before they need to be replaced.

Our coatings are applied once to a well-prepared surface and are expected to last the life of the vessel. At most minor touch-ups might be required in drydock to repair mechanical damage. The Corrosion Handbook has many examples of this being the case.

No excuses

The Corrosion Manual covers in simple, practical terms the handlings we have developed and that have proved so successful for these various types of corrosion in ships. It explains the problem, states the solution and provides ample case studies and customer feedback. It also provides practical information on applying the coatings both at newbuild stage and in drydock for vessels already in service, and explains which coating is used for what specific problem.

What you will not find anywhere in the Corrosion Manual is excuses for failure or reasons why certain parts of the ship will suffer from corrosion no matter what you do. We simply have not run into that situation.

Getting your hands on the Handbook

The Corrosion Handbook is not for sale. You will not find it online or in bookstores. If you would like your own copy, all you need do is email us at info@subind.net with a request for a copy or copies of the Corrosion Handbook plus your mailing address and we will send you your book free of charge – our contribution to putting an end to corrosion in ships.