Home - Marine coating systems - Corrosion damage repair

Corrosion damage repair

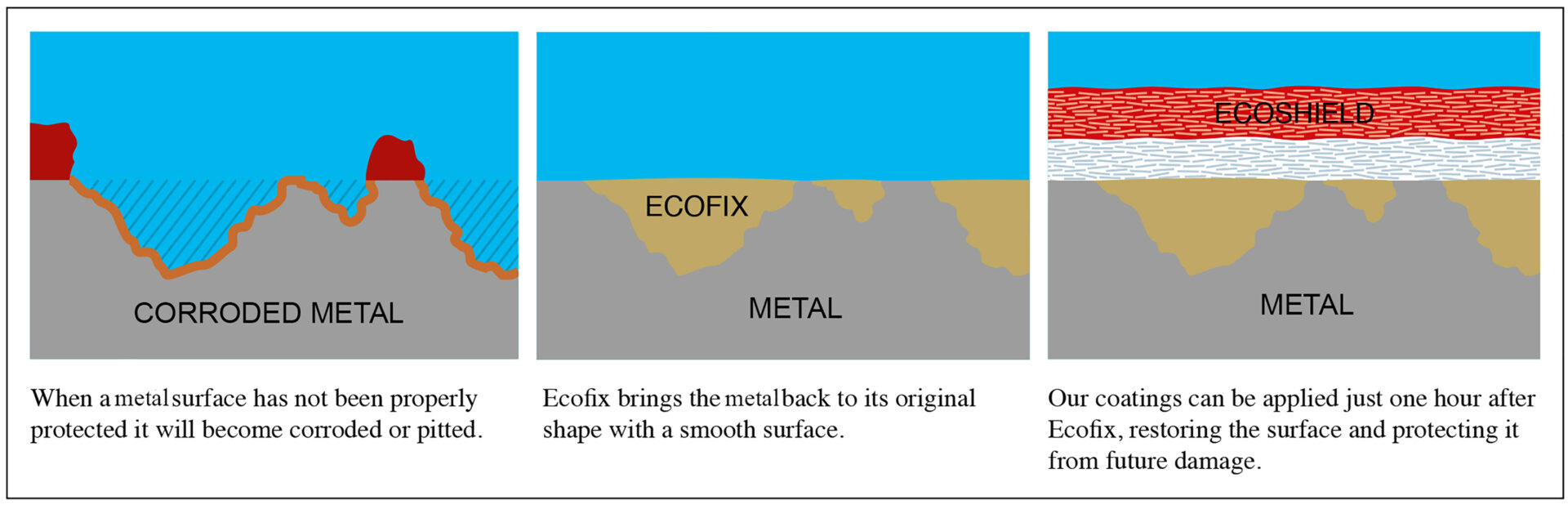

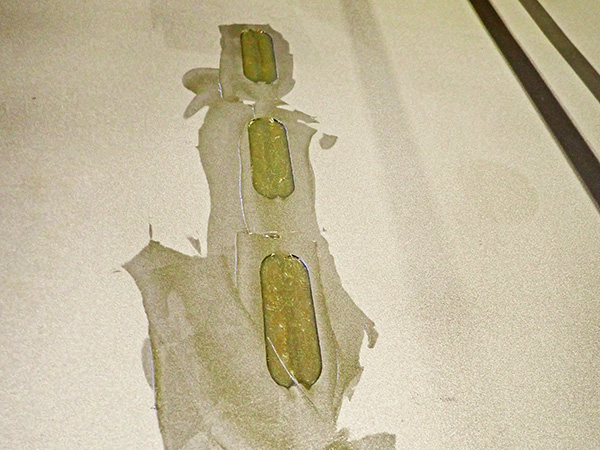

When a rudder or other piece of underwater ship gear has not been properly protected, the surface will become corroded and eroded. Cavitation damage can cause severe pitting. The steel needs to be restored to its original shape with a smooth surface prior to applying a proper protective coating. Ecofix is used in combination with Ecoshield, to fully repair the surface and then protect it for life. At newbuild it is used to fill weld slots for a smooth surface.

Ecofix can replace hot work in rudder and running gear repair

When a ship comes into drydock, maintenance of its rudder and running gear can be expensive and time-consuming. Cavitation and corrosion damage repair often involves hot work, resurfacing and grinding. Thus a poorly protected and damaged rudder or other running gear can extend drydocking time and costs considerably.

This is where Ecofix comes in. It is a superior, tested and proven filler. Because it uses the same basic resin as Ecoshield, the coating can be applied just one hour after the filler. The bonding and hardness are extraordinary.

This is the effective alternative to metal facing or very expensive (and time-consuming) alternative fillers. And because it is part of the Ecospeed/Ecoshield family, it is fully compatible with the coating. Ecofix can usually replace hot work in repairing pitted and corroded metal.

Ecofix can replace hot work in rudder and running gear repair

When a ship comes into drydock, maintenance of its rudder and running gear can be expensive and time-consuming. Cavitation and corrosion damage repair often involves hot work, resurfacing and grinding. Thus a poorly protected and damaged rudder or other running gear can extend drydocking time and costs considerably.

This is where Ecofix comes in. It is a superior, tested and proven filler. Because it uses the same basic resin as Ecoshield, the coating can be applied just one hour after the filler. The bonding and hardness are extraordinary.

This is the effective alternative to metal facing or very expensive (and time-consuming) alternative fillers. And because it is part of the Ecospeed/Ecoshield family, it is fully compatible with the coating. Ecofix can usually replace hot work in repairing pitted and corroded metal.

Ecofix at newbuild

Ecofix is the ideal way to fill weld slots in rudders and running gear quickly and inexpensively, prior to application of Ecoshield or Ecospeed.

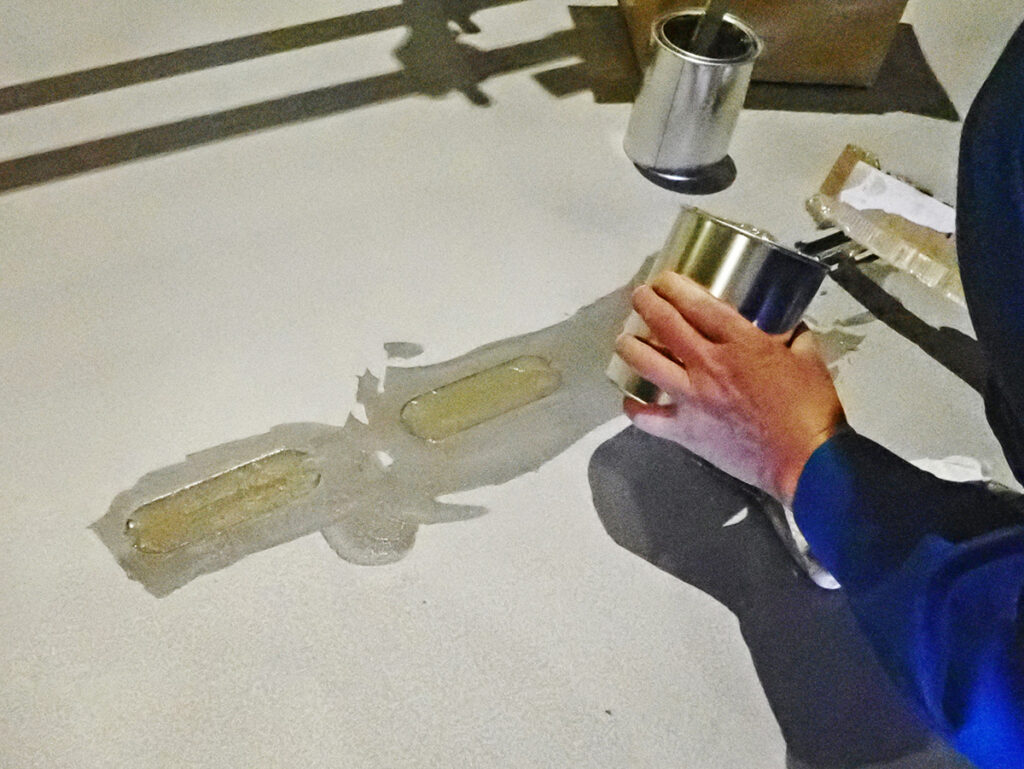

Exofix is very easy to apply and smooth. Ecoshield or Ecospeed can be applied just one hour after the Ecofix. Because the basic chemical composition is the same, the products work perfectly together.

Ecofix and Ecoshield used in combination are the perfect answer to rudder and running gear corrosion and erosion repair and protection.

Contact us for more information or a quote for an upcoming project

Do you have a newbuild or docking coming up that you feel Ecofix would be the perfect fit for? Contact us now and we will answer your questions and provide a quote for the project.

References, technical materials and further information for download

There is a wealth of information on Ecofix and our other products available in the form of books, white papers, case studies, magazine articles, technical guides, brochures and other literature.