EXMAR chooses Ecolock to coat the hull of its first-of-a-kind floating LNG liquefaction, and storage unit, the Caribbean FLNG

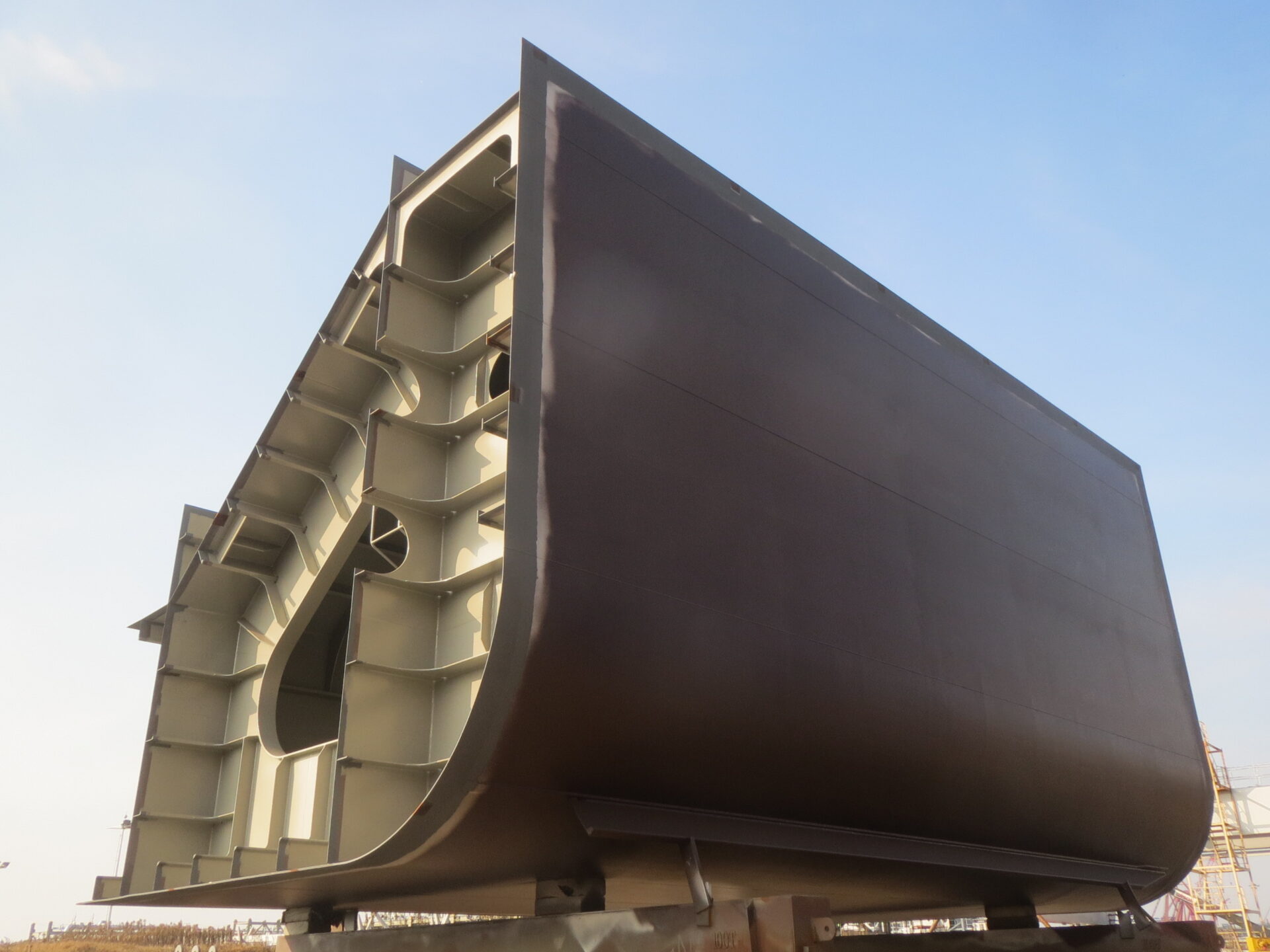

In order to tap into Colombian stranded gas reserves, Pacific Rubiales Energy Corporation and EXMAR nv partnered in a project to build and operate a floating LNG liquefaction, and storage unit, the Caribbean FLNG, which was built to be stationed at a jetty several kilometers off the Caribbean coast of Colombia for at least 15 years. In order to protect the hull of the Caribbean FLNG, keep it clean and facilitate class inspections over that time period without recourse to drydock and without causing harm to the local marine environment, EXMAR applied an innovative glassflake, non-toxic, long-lasting hull coating system, Ecolock, on the vessel’s hull. EXMAR is a pioneer in offshore processing and storage solutions so the choice of Ecolock was appropriate.

“We wanted to select a coating which can ensure that the underwater hull will not corrode for at least 15 years.”

EXMAR innovation and the Caribbean FLNG

Protecting the hull for 15 Years – ECOLOCK

A key requirement for the Caribbean FLNG was that it be able to stay moored at the jetty in Morrosquillo Bay for at least 15 years without the need to drydock.

In-water cleaning

Operating in tropical waters means that the rate of fouling growth is likely to be very high. Although fuel efficiency is obviously not a factor since the barge would not be going anywhere, the use of soft coatings such as biocidal antifouling or foul release paints would not be able to withstand the onslaught of barnacles and coral and other fouling organisms without penetration right through to the steel. This type of paint could not be cleaned in the water without severe damage to the coating. And these types of paint are toxic and emit heavy metals and/or other toxic substances which would not be tolerable in the sensitive Caribbean waters where the FLNG will be stationed.

Ecolock on the other hand has been proven to be impenetrable by marine organisms. It can be cleaned as often as needed by divers using rotating brushes and other tools and so brought back to its original pristine condition. The cleaning process does not produce any pollution or contamination. Nor does it damage the coating.

It remained to EXMAR and Hydrex to work out the optimum cleaning regimen for the ship. One full cleaning per year suffices. While it would be possible to clean the hull only once every five years prior to class inspection, the level of growth after that period of time will be very considerable and the time and cost required for cleaning would be significantly more than if the hull were cleaned annually and the fouling thus kept to a lower level of growth.

Ecolock on the other hand has been proven to be impenetrable by marine organisms.

Applying Ecolock

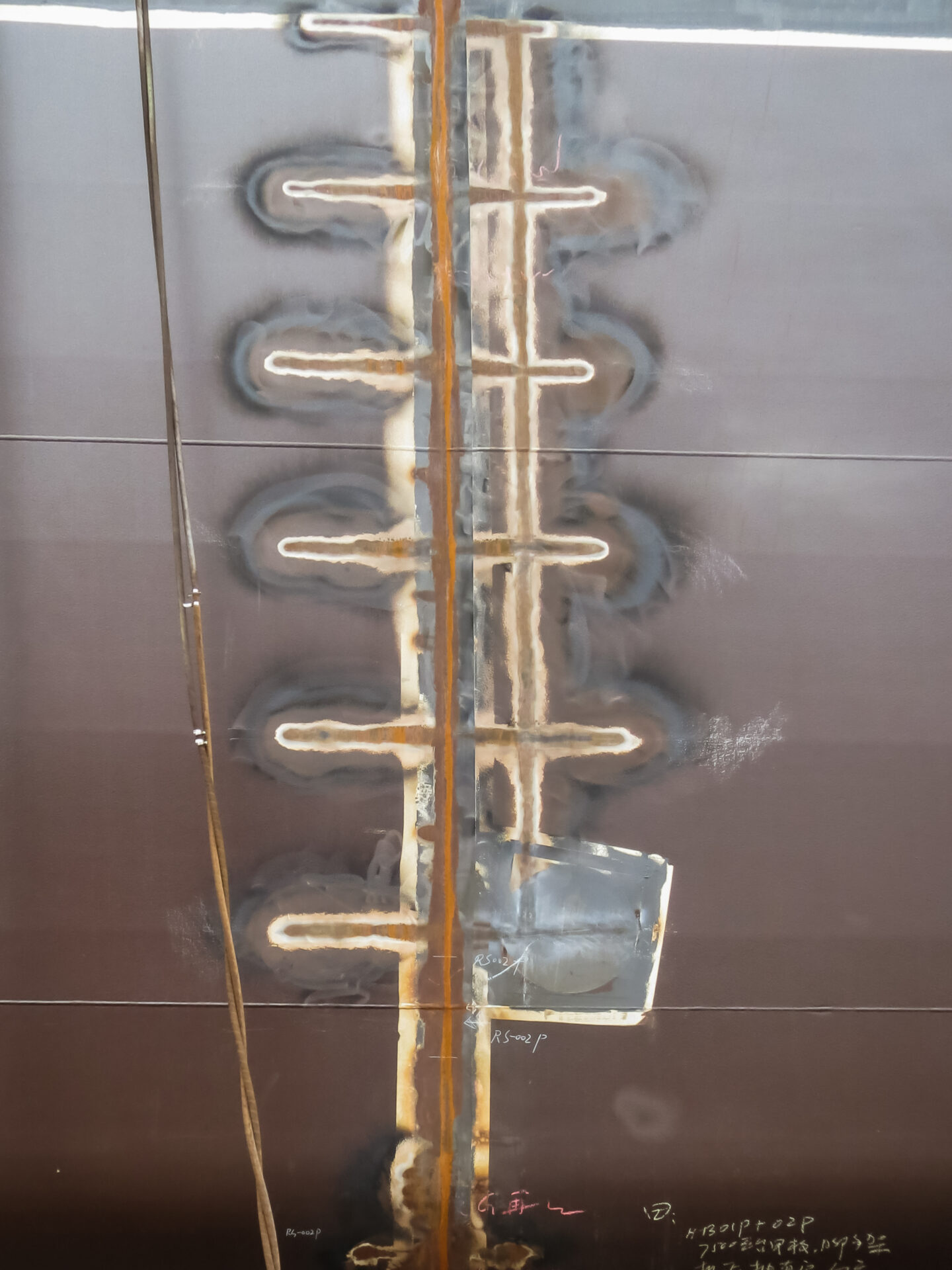

The barge was built in blocks and these blocks were coated individually before assembly, leaving only the weld seams and the areas inaccessible due to the support blocks to be painted after the barge was assembled.

Application of Ecolock can be done at newbuild or, to replace another coating, in drydock after the vessel has been in service. The new-build option is ideal. In either case the surface preparation requires a profile of at least 75μm and white or near-white steel (SA 2.5 or better). Once the preparation has been carried out and inspected, Ecospeed can be applied rather rapidly. No primer or other type of coating is required. Just two or more coats of Ecolock each of 500μm with an overcoat time of about three hours minimum and no maximum.

Coatings Inspect0r

As with all Ecolock applications, a trained and qualified paint inspector was on site supervising the preparation and application to assist with adherence to the manufacturers specifications at each step of the process, to help with training applicators where they have not previously applied Ecolock as in this case, and to assist with any problems that may arise. This is essential for a coating that is intended to last the life of the ship and which will carry a 10- or 15-year warranty. In this case, the inspector was Raul Yu who has supervised many successful Ecolock and other Subsea Industries applications in China.

Raul Yu provides some insight into the application, none of which is a surprise for a shipyard’s and applicator’s first experience with Ecolock. As usual with anything new, there was some initial reluctance to change from the traditional coating systems which the yard and applicators were familiar with.

Two applicator companies carried out the blasting and spraying of the Caribbean FLNG: the application to the blocks in the painting workshop was done by Nantong Hengrong Marine Engineering Co. Ltd. and the subsequent finishing job at the drydock was done by COSCO (Nantong) Clavon Engineering Co. Ltd. This was a first time application of Ecolock for both companies and for the Wison yard.

Easy to apply

“The applicators had not worked with Ecolock before,” explains Raul Yu. “I gave them the necessary instructions and had them apply Ecolock on a small test patch. This gave them a practical feeling of an Ecolock application. During the spraying of the first block, they found that Ecolock application is actually quite easy. They realized that if the specifications are followed by the coating subcontractor, the application goes very well and smoothly. Compared to traditional coating systems with multi-layers, Ecolock coating saves them much time as after surface preparation only two similar Ecolock coats each of 500μm DFT need to be applied. Because of the short interval required between coats (three hours at 20° Celsius), a block can be fully coated with two coats in the same day. The senior coating sprayer who has more than 12 years spraying experiences in different shipyards both in China and Japan was amazed at such a high application rate. Raul adds that, “while we are strict on the pot life and the thorough cleaning of spray equipment, in general Ecolock application is like that of any other coating system.” The preparation also has to be done to exact specifications.

Finishing in drydock

The uncoated areas where the supports for the blocks prevented preparation and coating in the paint shop were subsequently prepped and painted in drydock so that the entire hull was full coated.

Caribbean FLNG was a first for the Wison shipyard. According to Raul Yu, “Wison are very satisfied with Ecolock due to the ease and speed of application as well as the quality of the coating. They told me that had the hull been coated with a traditional coating system it would have taken at least seven days from surface preparation to the final coat, but Ecolock has changed this completely. Two coats in a single day minimized the risk associated with multi-layer applications, saved time, labor costs, operation costs and other related expense.

“Also there is almost no chemical smell during the spraying, in comparison with other paints. This makes the application environment comfortable for the sprayer. They now understand why Ecospeed is so named: Eco for Economical and nontoxic environmentally, and Speed for the fast application and short overcoat interval. They said that Ecospeed/Ecolock is worthy of the name, a really high quality coating system.” (Note that this is before the ship even left the yard. The economic, ecologic and speed factors are even more noticeable when the ship is operating.)

Because the Ecolock system (and all the Subsea Industries family of coatings) consists of a single, homogenous covering of the steel, painting over weld seams after the blocks have been assembled is very easy and leaves a smooth finished surface, the erection joint paint blending in perfectly with the coating of the rest of the hull.

(the article continues after the slideshow)

Second EXMAR Ecolock Project – Newbuild FSRU

Following the success of the Caribbean FLNG, in the second half of 2015 application of Ecolock started on a newbuild Floating Storage and Regasification Unit (FSRU) in China.

As with the first project, the FSRU was built in blocks. These blocks were coated individually before assembly, leaving only the weld seams and the areas inaccessible due to the support blocks to be painted after the barge was assembled. The Ecolock system consists of a single, homogenous covering of the steel. Painting over weld seams after the blocks have been assembled is very easy. It leaves a smooth finished surface and the erection joint paint blends in perfectly with the coating of the rest of the hull.

Ecolock comes with a 10, 15 or 20 year warranty as long as it is standardly applied and if the coating is maintained according to the specifications.

Ecolock is an extremely tough and durable coating designed to remain in excellent condition for 15 – 25 years without drydocking, repair or replacement. Ecolock can be cleaned underwater as often as needed to meet the UWILD and weight requirements of FPSOs, drill ships and other offshore vessels. Ecolock is the result of continual R&D on offshore hull coatings since the 1990s.