Beneath the surface of the sea, lakes, rivers and other bodies of water, lies hidden one of the planet’s most serious problems: polluted, contaminated sediment. A key contributor to this situation is the continual emission of toxic and polluting substances into the water from the hulls of ships, due to the coatings in general use. Fortunately there is an alternative.

Antifouling coatings

The most commonly used type of ship hull coating, biocidal antifouling paint, is designed to continuously leach heavy metals and other biocides into the water to deter marine life. The paint is applied at newbuild or in drydock and by the time the ship comes back to drydock after two and a half or five years (for yachts it’s usually every year), the biocidal topcoat has all gone and needs to be replaced. The heavy metals and toxic substances have leached into the water and from there drop down to the sediment where they remain.

Global copper release from antifouling paints is estimated at 20,000 – 40,000 metric tons per year for the commercial shipping fleet. Total annual biocide releases from leisure craft are estimated to be several thousand metric tons. The concerns are contamination and bioaccumulation. Many scientific papers exist on the dangers of this chemical overload to the planet’s waters and the life forms that live in them or depend on them.

Foul release coatings

Foul release coatings, despite often being advertised as “biocide free,” also contaminate and pollute the water and sediment. “Biocide free” just means that the paint doesn’t contain any of the chemicals listed as biocides by the IMO, the EU and other regional regulatory bodies. And yet many of these coatings contain large quantities of dibutyltin (DBT), an organotin which is a close cousin to the infamous TBT which has caused so much harm to the marine environment and continues to do so even though it has long since been banned as an antifouling biocide. The toxic chemicals in FR paint experience the same fate as those in AF coatings.

There are additional pollutants from ship hull coatings which include silicone oils, microplastics and PFAS.

Dangerous effects

Contaminated sediment around the world is added to every day as 100,000+ ships and 20-25 million smaller boats and recreational craft ply the world’s oceans, seas, rivers and lakes, leaving a trail of poisonous chemicals in their wake.

There are very large areas that cannot be dredged because the contaminated sediment will be resuspended with fatal results on subaquatic life. The contaminants (poisons) can go all the way up the food chain and become part of our diet.

This is a disaster in the making, or rather, a disaster already created. The fact that these poisons and other pollutants are sanctioned by the IMO and other regulatory bodies does not make them any less poisonous or harmful.

Choices

The arguments used to continue this unsustainable course of action are that antifouling and foul release coatings are needed in order to keep fuel consumption and thus greenhouse gas emissions down as much as possible, and to help prevent the spread of non-indigenous aquatic species. Another argument is that the chemicals in question are not really that harmful.

These arguments might have some validity if there were no alternative.

However, there is an alternative which can protect ship and boat hulls for their useful life without the need for recoating. It does not emit any toxic chemicals into the water. This solution, if used properly, can greatly improve long-term fuel performance of hulls compared to AF or FR coatings. It eliminates the transfer of invasive species.

Founding of Subsea Industries

Hydrex founder Boud Van Rompay became aware of this situation as a result of his commercial diving and ship hull cleaning activities beginning in the 1970s. He recognized that what was needed to turn the tap off on the steady and continuous pollution of the world’s waterways was a system for protecting ship hulls and ensuring high fuel efficiency without the use of poisonous chemicals.

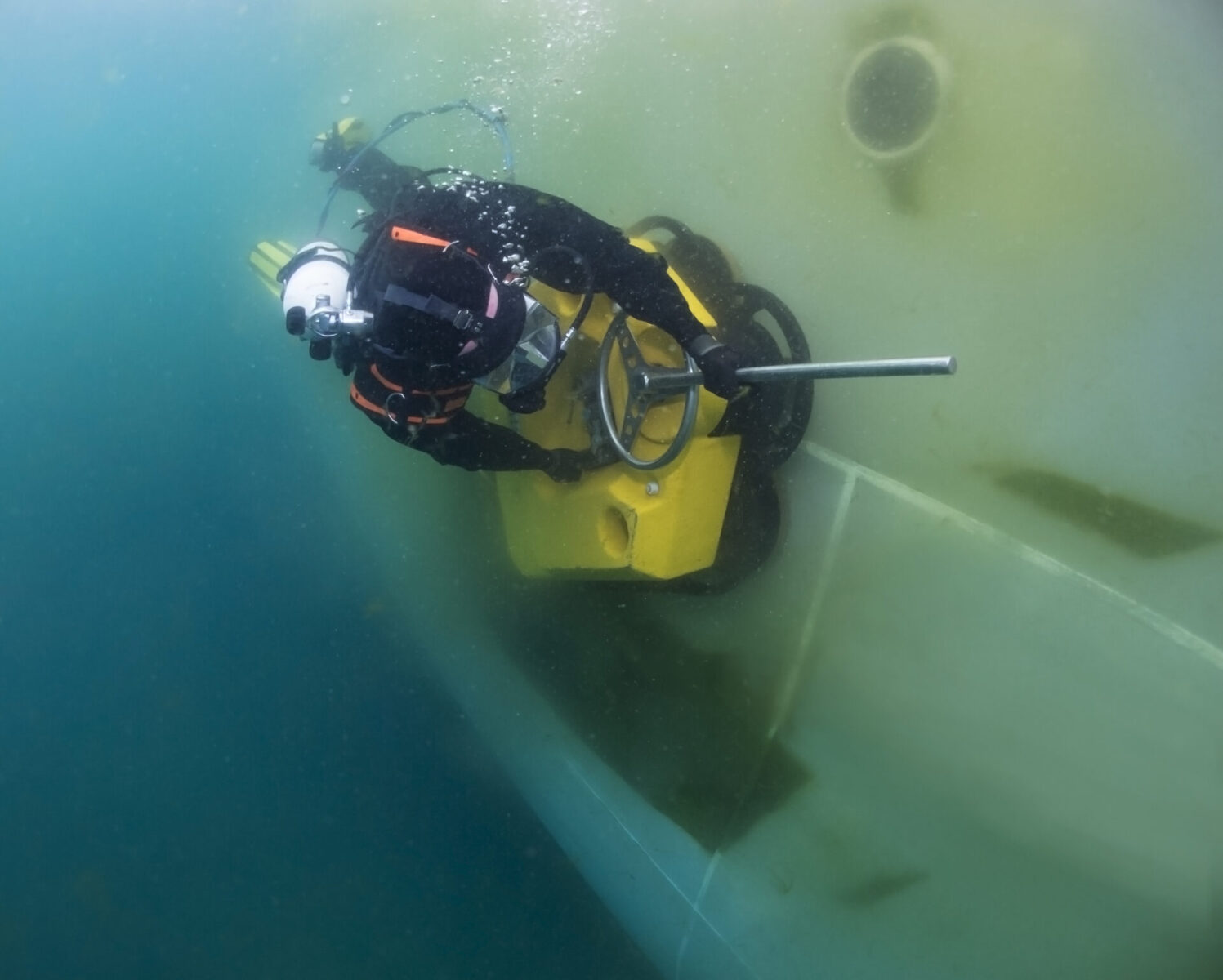

After years of development and testing, Ecospeed emerged as the solution. It is a system consisting of a very tough and durable coating which is completely inert, has no active ingredients and does not emit anything into the water; this is combined with cleaning as needed to remove biofouling. The cleaning can be done in or out of the water. Ecospeed is a system which replaces the use of chemicals with some honest to goodness elbow grease. Taking all aspects into consideration, it represents a considerable cost savings for the shipowner. Most importantly, its use does not worsen the widespread situation of contaminated sediment.

Since the launch of Ecospeed in 2002, Subsea Industries’ family of non-toxic coatings has expanded to include Ecoshield, a tougher version designed to protect rudders and running gear from cavitation damage, and Ecolock – long-term, non-toxic, cleanable protection for offshore, assets guaranteed for up to 35 years.

Real non-toxic coatings

The Ecospeed family of coatings are hard, non-toxic protection consisting of a high proportion of glass platelets in a vinyl ester resin. The only other ingredients are bonding agents and pigments.

Independent testing by more than one laboratory has established that Ecospeed does not emit any toxic chemicals on application, in use, or during conditioning and cleaning in the water.

In March 2010, the independent Belgian testing laboratory ERM (Environmental Resources Management) issued its findings after testing Ecospeed: “The toxicity tests performed on the water samples demonstrated that the released substances were harmless. Also no effect on the estrogen activity could be recognized.”

In July 2012, a Washington State, US lab, Nautilus Environmental, was tasked with conducting toxicity tests on Ecospeed as part of a process for obtaining permission from WA State Ecology and Fish & Wildlife departments to clean the underwater hulls of ships coated with Ecospeed in the waters of the notoriously strict Washington Sate. No adverse effects were observed as a result of exposure to Ecospeed in water in the organisms used for the toxicity testing[1]. The head of WA State Dept. of Ecology was satisfied that there was no danger in allowing Ecospeed to be cleaned in Washington State waters (where cleaning of traditional hull coatings is strictly forbidden)[2].

In practice this means that a ship hull can be coated and in service for 20 or more years without emitting a single gram of toxic substances into the marine environment. Used properly, it can also deliver at least 10% fuel savings compared to AF or FR coatings, and can completely eliminate the threat of spreading invasive aquatic species. The lifecycle cost savings are considerable, especially when fuel savings are included in the calculation.

There is another major advantage to using a completely non-toxic coating: the rules change, as has been shown in the past. The use of toxic coatings is under constant scrutiny. It is much safer for a shipowner to future-proof his investment in hull coating by using a completely non-toxic solution which will always be compliant, no matter how the regulations evolve.

Bottom line

The Ecospeed family of coatings lives up to the purpose for which it was conceived. They are the answer to stopping the continual marine and sediment pollution by ship hull coatings. They are also a solution which will remain compliant no matter how the regulations concerning toxic emissions from ship hull coatings evolve.

It’s time to completely turn off the tap on the flow of toxic substances into our planet’s waters. It can only take so much, and it’s already seriously suffering.

[1] Nautilus Environmental Toxicity testing for Ecospeed October 10, 2012

[2] Email correspondence with Randall Marshall, WA State Dept of Ecology 17 November, 2020