Home - Marine coating systems - Hull protection and performance

Hull protection and performance

Ecospeed is a hull coating system which provides long-lasting, non-toxic protection for all ship hulls. The hull is kept very smooth and free of fouling for the service life of the vessel. It requires minimal repair and no replacement. Correct use of the system results in major fuel savings compared to conventional coating systems.

Instead of using chemicals to try to kill and repel marine fouling organisms, Ecospeed uses a hard coating along with manual or mechanical removal of fouling at an early stage.

1. One-of-a-kind coating

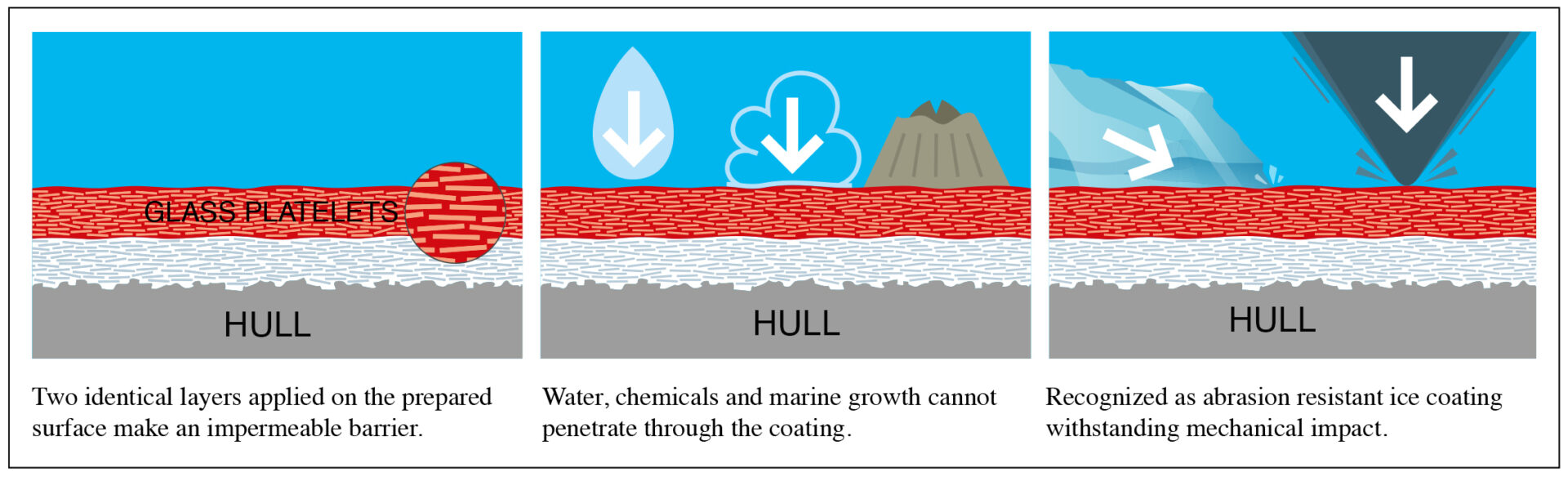

Ecospeed is a glass platelet reinforced composite coating that is impermeable, long-lasting, inert and non-toxic. It is usually applied in two coats each of 500 μm dry film thickness (DFT) to a properly prepared steel, aluminum or GRP hull.

This can be at new build (ideal) or in drydock for an in-service vessel. Overcoat time is 3 hours minimum, no maximum. This coating has extraordinary adhesion and bonding qualities. It is very tough and resistant to abrasion and is certified ice-abrasion resistant. It is also flexible and remains firmly bonded to the plates even when these flex considerably.

2. Routine underwater cleaning

The coating is cleaned routinely to keep it smooth and free from slime and weed. This is done in the water using specially developed equipment and tools. Even extreme hard fouling can be removed without damage to the coating or the marine environment.

Frequency of cleaning depends on the operating pattern and environment of the ship. The cost of cleaning is dwarfed by the fuel savings.

3. Touch-ups in drydock

The coating is expected to last the full service life of the ship without need for replacement or any major repair.

Mechanical damage such as that caused by collision or anchor chain abrasion or by welding on the hull or other causes can easily be touched up during routine drydocking. Because the coating consists of a single, homogenous layer, any repair or touch-up easily blends in without any difficulty. The integrity of the hull coating is maintained despite such repairs. Because no repaint is needed, several days and up to a week can be saved in drydock times during each visit.

Miscellaneous applications

Ecospeed’s extraordinary toughness, chemical resistance and strong bonding make it suitable for many applications where an ordinary coating simply will not hold up:

- Scrubber outlets and surrounding hull area

- Decks of RoRo vessels and others requiring wear resistance

- Ballast tanks

- Other applications

References, technical materials and further information for download

There is a wealth of information on Ecospeed and our other products available in the form of books, white papers, case studies, magazine articles, technical guides, brochures and other literature.

Contact us for more information or a quote for an upcoming project

Do you have a newbuild or docking coming up that you feel Ecospeed would be the perfect fit for? Contact us now and we will answer your questions and provide a quote for the project.